Introduction

As global power transmission networks expand and modernize, high-voltage underground and submarine cable systems have become essential for reliable electricity delivery. Among all accessories used in these systems, 132kV cable straight joint splices play a critical role in ensuring electrical continuity, mechanical strength, and long-term insulation integrity.

A 132kV cable straight joint splice is used to connect two lengths of high-voltage power cable into a single continuous circuit. These joints must withstand high electrical stress, thermal cycling, environmental exposure, and mechanical forces over decades of service life. For this reason, professional utilities, EPC contractors, and grid operators rely on factory-engineered cable joint kits manufactured in accordance with IEC and ASTM standards.

What Is a 132kV Cable Straight Joint Splice?

A straight joint splice is a cable accessory used to join two cables of the same voltage rating and construction in a straight line without changing direction. In 132kV high-voltage systems, straight joints are commonly used in:

- Long-distance underground transmission lines

- Submarine cable routes

- Power plant connections

- Urban and industrial grid networks

- Tunnel and duct installations

Unlike terminations, straight joints must maintain the same insulation and electrical performance as the original cable. Any weakness in the joint can lead to partial discharge, insulation breakdown, or catastrophic failure.

Typical Applications of 132kV Cable Straight Joints

132kV straight joint kits are widely applied in:

- Underground power transmission projects

- Submarine and coastal cable systems

- Grid reinforcement and expansion

- Cable repair and replacement projects

- Transition joints between different conductor materials

They are suitable for XLPE insulated copper or aluminum power cables, including single-core and three-core designs.

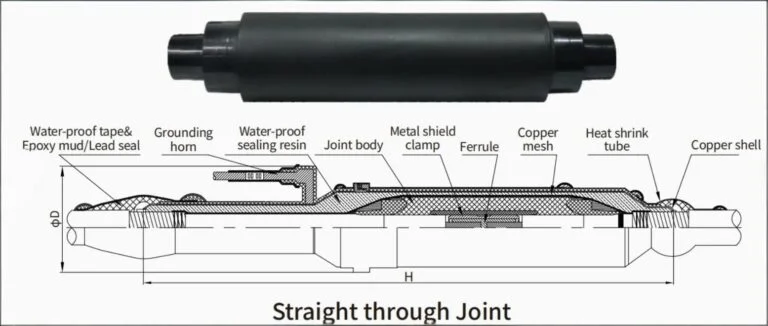

Key Design Requirements for 132kV Straight Joint Splices

To operate safely and reliably at high voltage, a 132kV cable joint must meet several strict design requirements:

1. Electrical Stress Control

High electric fields concentrate at conductor cutbacks. Stress control components, such as geometric stress cones or resistive stress control layers, are essential to prevent partial discharge.

2. Insulation Continuity

The joint insulation must match or exceed the dielectric performance of the cable insulation, typically XLPE or EPR.

3. Thermal Performance

Joints must withstand continuous current loading and short-circuit conditions without overheating or insulation degradation.

4. Mechanical Strength

The joint must maintain conductor alignment and mechanical integrity under thermal expansion and contraction.

5. Environmental Protection

Moisture, water ingress, chemical exposure, and soil contamination must be prevented through robust outer protection layers.

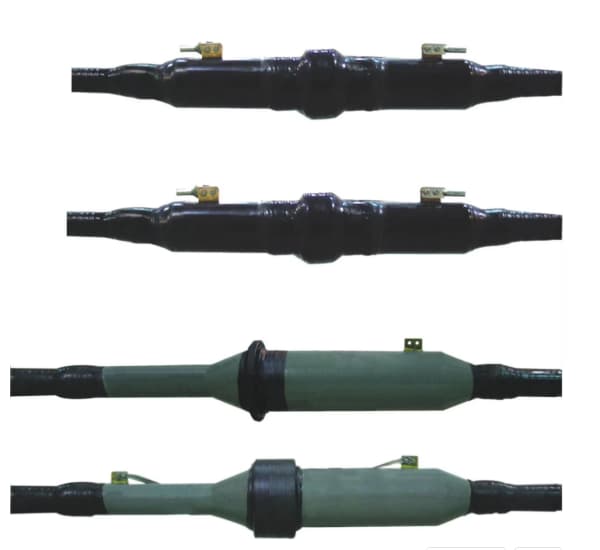

Main Types of 132kV Cable Straight Joint Splices

1. Pre-Molded Straight Joint Kits

Pre-molded joints are factory-manufactured silicone or EPDM components designed to be slipped over the cable.

Advantages:

- Consistent factory quality

- Short installation time

- Low risk of installation errors

Typical use: Utility and EPC projects requiring high reliability.

2. Heat Shrink Straight Joint Kits

These joints use heat-shrinkable insulation tubes and stress control components.

Advantages:

- Flexible installation

- Suitable for various cable sizes

- Cost-effective for certain projects

Typical use: Industrial and repair applications.

3. Cold Shrink Straight Joint Kits

Cold shrink joints are supplied pre-expanded on removable cores.

Advantages:

- No heat required

- Excellent environmental sealing

- Easy installation in confined spaces

Standards for 132kV Cable Joint Kits

Professional cable kits manufacturers design 132kV straight joints according to international standards, including:

- IEC 60840 – Power cables with extruded insulation above 30kV

- IEC 62067 – Power cables above 150kV (applied for design reference)

- IEEE 404 – Extruded dielectric cable joints

- ASTM B8 / B231 / B232 – Conductor standards

- IEC 60228 – Conductors of insulated cables

Compliance with these standards ensures long-term electrical reliability and global project acceptance.

IEC Conductor Cross-Section Range for 132kV Cable Joints

IEC standards define conductor sizes using metric cross-sectional areas (mm²). A professional 132kV cable straight joint kit manufacturer typically covers a wide range of conductor sizes.

Table 1: IEC Conductor Cross-Sections for 132kV Cable Straight Joint Splices

| IEC Conductor Size (mm²) | Typical Material | Application |

|---|---|---|

| 50 mm² | Copper / Aluminum | Small transmission circuits |

| 70 mm² | Copper / Aluminum | Utility distribution |

| 95 mm² | Copper / Aluminum | Medium-load systems |

| 120 mm² | Copper / Aluminum | Industrial networks |

| 150 mm² | Copper / Aluminum | Urban transmission |

| 185 mm² | Copper / Aluminum | Grid reinforcement |

| 240 mm² | Copper / Aluminum | High current circuits |

| 300 mm² | Copper / Aluminum | Main transmission feeders |

| 400 mm² | Copper / Aluminum | Heavy-duty networks |

| 500 mm² | Copper / Aluminum | Long-distance transmission |

| 630 mm² | Copper / Aluminum | High-capacity systems |

| 800 mm² | Copper / Aluminum | Utility backbone |

| 1000 mm² | Copper / Aluminum | Extra-high current |

| 1200 mm² | Copper / Aluminum | Power plant output |

| 1600 mm² | Copper / Aluminum | Special projects |

| 2000 mm² | Copper / Aluminum | Submarine applications |

| 2500 mm² | Copper / Aluminum | Ultra-high current |

ASTM (American Standard) Conductor Sizes for 132kV Cable Joints

In North America and some international markets, conductor sizes follow ASTM and AWG/kcmil standards.

Table 2: ASTM / AWG Conductor Sizes for 132kV Cable Straight Joint Kits

| ASTM / AWG Size | Approx. Area (mm²) | Typical Application |

|---|---|---|

| AWG 1/0 | 53.5 mm² | Distribution circuits |

| AWG 2/0 | 67.4 mm² | Utility networks |

| AWG 3/0 | 85.0 mm² | Medium current |

| AWG 4/0 | 107.2 mm² | Industrial systems |

| 250 kcmil | 126.7 mm² | Transmission feeders |

| 350 kcmil | 177.3 mm² | Urban grids |

| 500 kcmil | 253.4 mm² | High load circuits |

| 750 kcmil | 380.0 mm² | Utility backbone |

| 1000 kcmil | 506.7 mm² | High-capacity lines |

| 1250 kcmil | 633.4 mm² | Substation output |

| 1500 kcmil | 760.1 mm² | Power plants |

| 1750 kcmil | 886.8 mm² | Long-distance transmission |

| 2000 kcmil | 1013.4 mm² | Extra-high current |

| 2500 kcmil | 1266.8 mm² | Submarine cables |

Conductor Materials Supported

A professional 132kV cable straight joint splice manufacturer typically supports:

- Copper conductors (Cu)

- High conductivity

- Compact design

- Preferred for space-limited installations

- Aluminum conductors (Al)

- Lightweight

- Cost-effective

- Widely used in long-distance transmission

Bimetallic connectors are available to accommodate Cu-Al transitions when required.

Joint Insulation Technologies

XLPE Insulation Matching

Modern 132kV joints are designed to replicate the electrical performance of XLPE cable insulation, ensuring smooth electric field distribution.

Stress Control Systems

- Geometric stress cones

- Resistive stress control layers

- Semi-conductive shields

These components reduce electrical stress concentration at the conductor and insulation interface.

Installation Process Overview

Although installation procedures vary by joint type, a typical process includes:

- Cable preparation and sheath removal

- Insulation cutback and conductor cleaning

- Connector crimping or bolting

- Installation of stress control components

- Insulation rebuilding

- Metallic shielding restoration

- Outer protection and sealing

Proper installation by trained technicians is critical to achieving the full service life of the joint.

Testing and Quality Assurance

High-quality 132kV cable straight joint kits undergo rigorous testing, including:

- Partial discharge testing

- AC withstand voltage testing

- Thermal cycling tests

- Mechanical pull tests

- Water immersion tests

These tests ensure compliance with IEC and IEEE standards before project delivery.

Advantages of Choosing a Professional Cable Kits Manufacturer

Working with an experienced 132kV cable straight joint splice manufacturer offers:

- Full IEC and ASTM compliance

- Wide conductor size coverage

- Custom-engineered solutions

- Stable long-term performance

- Global project experience

132kV cable straight joint splices

132kV cable straight joint splices are a vital component of modern high-voltage power transmission systems. Their design, material selection, and installation quality directly impact the reliability and safety of underground and submarine cable networks.

By choosing a professional cable kits manufacturer that supports both IEC metric conductor sizes and ASTM American standards, utilities and contractors can ensure compatibility with global projects, reduced installation risk, and long-term operational stability.

As power grids continue to expand and modernize, high-quality 132kV cable straight joint kits will remain a cornerstone of safe and efficient energy transmission worldwide.