Introduction to ZTACIR Conductor

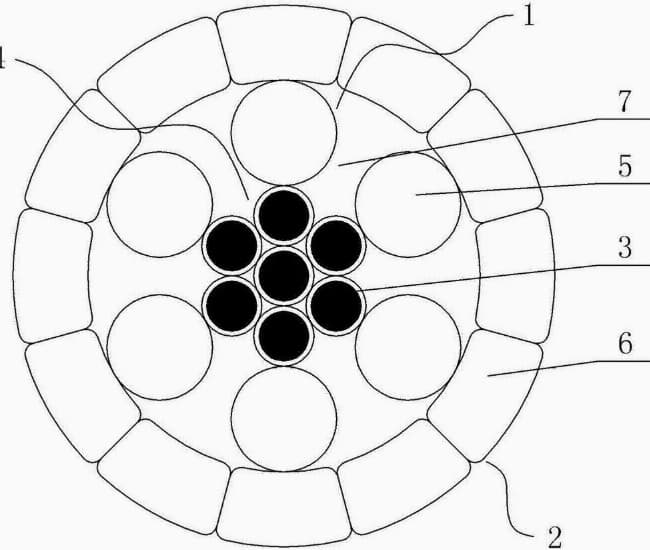

ZTACIR (Zirconium-Thermal Alloy Conductor with Invar Reinforcement) is a high-temperature low-sag (HTLS) conductor designed for modern power transmission needs. It offers superior thermal resistance, lower sag characteristics, and increased current carrying capacity compared to traditional conductors such as ACSR (Aluminum Conductor Steel Reinforced) or AAAC (All Aluminum Alloy Conductor).

As a leading ZTACIR conductor manufacturer, we provide high-performance conductors tailored to the demands of modern power grid infrastructure. Our ZTACIR conductors are engineered to optimize efficiency and reduce transmission losses, making them an ideal choice for upgrading existing lines and deploying new high-capacity power transmission networks.

Advantages of ZTACIR Conductor

- High-Temperature Performance: Operates at temperatures up to 210°C without compromising mechanical integrity.

- Low Sag Characteristics: Incorporates an invar (Fe-Ni alloy) reinforced core to minimize thermal expansion, reducing sagging at high temperatures.

- Enhanced Current Carrying Capacity: Supports higher ampacity compared to conventional conductors, allowing efficient power transmission.

- Corrosion Resistance: Zirconium-enriched aluminum alloy enhances oxidation and corrosion resistance, increasing the conductor’s lifespan.

- Lightweight yet High Strength: A combination of lightweight aluminum alloy and invar core provides excellent strength-to-weight ratio.

- Environmental Benefits: Reduced transmission losses contribute to a lower carbon footprint and increased energy efficiency.

Technical Specifications of ZTACIR Conductor

| Property | Specification |

|---|---|

| Conductor Type | HTLS (High-Temperature Low-Sag) |

| Core Material | Invar (Fe-Ni alloy) |

| Outer Layer Material | Zirconium-Aluminum Alloy |

| Operating Temperature | Up to 210°C |

| Rated Strength | Higher than ACSR and ACSS |

| Thermal Expansion Coefficient | Lower than ACSR |

| Ampacity Increase | 50-80% higher than ACSR |

| Corrosion Resistance | High |

| Sag Reduction | Significant compared to conventional conductors |

ZTACIR Conductor Model Specifications

| Model | Overall Diameter (mm) | Aluminum Area (mm²) | Core Area (mm²) | Rated Tensile Strength (kN) | DC Resistance at 20°C (Ω/km) | Current Capacity (A) |

| ZTACIR-240 | 20.6 | 240 | 42 | 84 | 0.115 | 760 |

| ZTACIR-300 | 23.2 | 300 | 52 | 105 | 0.092 | 890 |

| ZTACIR-400 | 26.7 | 400 | 67 | 130 | 0.072 | 1080 |

| ZTACIR-500 | 30.5 | 500 | 83 | 160 | 0.058 | 1250 |

| ZTACIR-600 | 33.0 | 600 | 98 | 185 | 0.048 | 1400 |

These specifications may vary based on customer requirements and regional power grid standards.

Applications of ZTACIR Conductors

ZTACIR conductors are widely used in modern transmission infrastructure due to their superior efficiency and reliability. Below are some of their key applications:

1. High-Voltage Power Transmission Lines

ZTACIR conductors are ideal for high-voltage (HV) and extra-high-voltage (EHV) transmission lines, offering reduced sag and enhanced current carrying capacity.

2. Upgrading Existing Power Lines

Replacing ACSR conductors with ZTACIR conductors allows utilities to increase power transmission capacity without changing tower structures. This is a cost-effective way to modernize power grids without extensive infrastructure modifications.

3. Renewable Energy Integration

ZTACIR conductors are essential for integrating solar and wind energy into power grids. Their high ampacity allows them to transmit large amounts of energy over long distances with minimal losses.

4. Urban Power Transmission

In densely populated areas where transmission corridors are limited, ZTACIR conductors help utilities maximize power transmission within existing rights-of-way.

5. Overhead Transmission in Harsh Environments

Due to their corrosion-resistant properties, ZTACIR conductors are well-suited for coastal regions, industrial zones, and areas with extreme weather conditions.

6. Industrial Power Distribution

Heavy industries such as mining, steel production, and chemical plants require high-capacity power transmission, making ZTACIR conductors a reliable solution for these applications.

Comparison: ZTACIR VS ACSR VS ACSS Conductors

| Feature | ZTACIR Conductor | ACSR Conductor | ACSS Conductor |

| Operating Temperature | Up to 210°C | 75-90°C | 200°C |

| Sag Performance | Low | High | Medium |

| Strength-to-Weight Ratio | High | Medium | Medium |

| Corrosion Resistance | High | Medium | High |

| Ampacity | High | Medium | High |

| Cost Efficiency | High | Medium | Medium |

Why Choose Our ZTACIR Conductors Manufacturer?

As a professional ZTACIR conductor manufacturer, we offer:

✔ Customized Designs – Tailored specifications to meet regional power grid requirements.

✔ High-Quality Materials – Zirconium-Aluminum alloy and invar core for maximum performance.

✔ Advanced Manufacturing Process – Precision engineering and rigorous quality testing.

✔ Global Supply Chain – Fast and reliable delivery across different regions.

✔ Technical Support – Expert consultation for optimal conductor selection and installation.

Conclusion

ZTACIR conductors represent the future of power transmission, offering high-temperature resistance, low sag, and superior ampacity. Whether upgrading existing lines or constructing new high-voltage networks, these conductors provide a cost-effective and energy-efficient solution for modern power grids.

As a trusted ZTACIR conductor manufacturer, we are committed to delivering high-performance conductors to meet the demands of the evolving energy sector. Contact us today for more information or to request a quote!