Overview

As power transmission systems continue to evolve, utilities and grid operators are facing increasing pressure to transmit more electricity over existing infrastructure. Higher current loads, longer spans, and extreme temperature variations often expose the limitations of conventional conductors. In this context, Aluminum Clad Invar Cable Conductor Wire has become a preferred choice for modern overhead transmission projects.

By integrating an Invar alloy core with an aluminum outer layer, this conductor delivers a unique balance of electrical efficiency and mechanical stability. Its extremely low thermal expansion makes it especially suitable for high-temperature, low-sag (HTLS) applications, where maintaining safe ground clearance and mechanical integrity is critical.

This article explains the concept, structure, performance characteristics, and real-world applications of aluminum clad Invar cable conductor wire. Related terms such as aluminum clad Invar conductor, Invar core aluminum cable, low thermal expansion overhead wire, and Invar reinforced transmission conductor are naturally incorporated throughout the content.

Definition of Aluminum Clad Invar Cable Conductor Wire

An Aluminum Clad Invar Cable Conductor Wire is a composite overhead conductor designed for power transmission lines that require high mechanical strength with minimal thermal elongation. Unlike traditional steel-core conductors, this conductor uses Invar alloy as its load-bearing core and aluminum as the conductive outer layer.

Why Invar Is Used as the Core

Invar is an iron–nickel alloy known for its exceptionally low coefficient of thermal expansion. When used as a conductor core, Invar significantly reduces the length variation caused by temperature changes, which directly improves sag performance.

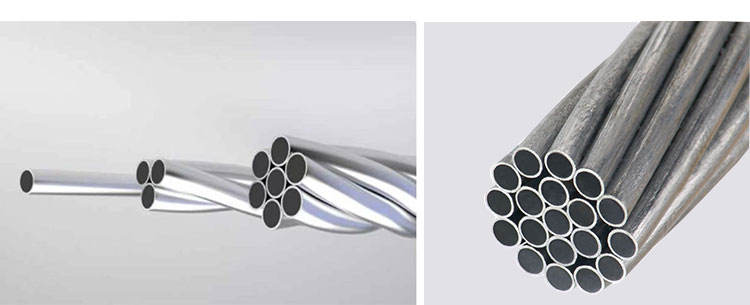

Role of the Aluminum Cladding

The aluminum cladding or aluminum strands surrounding the Invar core serve multiple purposes:

- Conduct electrical current efficiently

- Provide corrosion resistance

- Improve overall conductor flexibility

- Ensure compatibility with standard fittings and accessories

Together, these materials create a conductor optimized for demanding overhead transmission conditions.

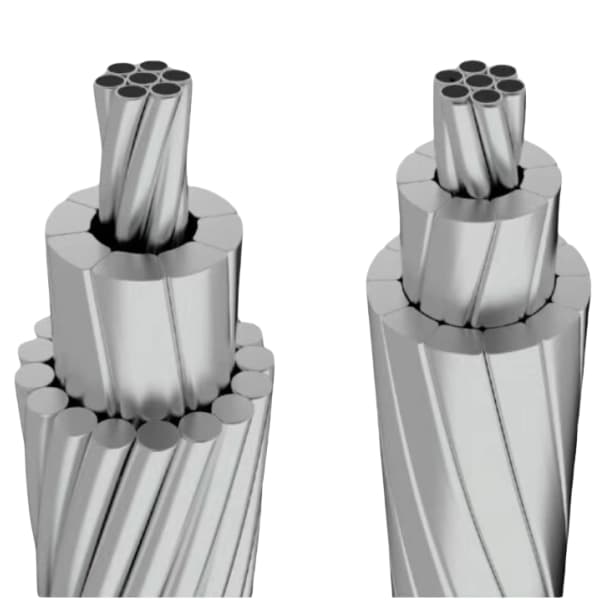

Structural Characteristics of Aluminum Clad Invar Conductors

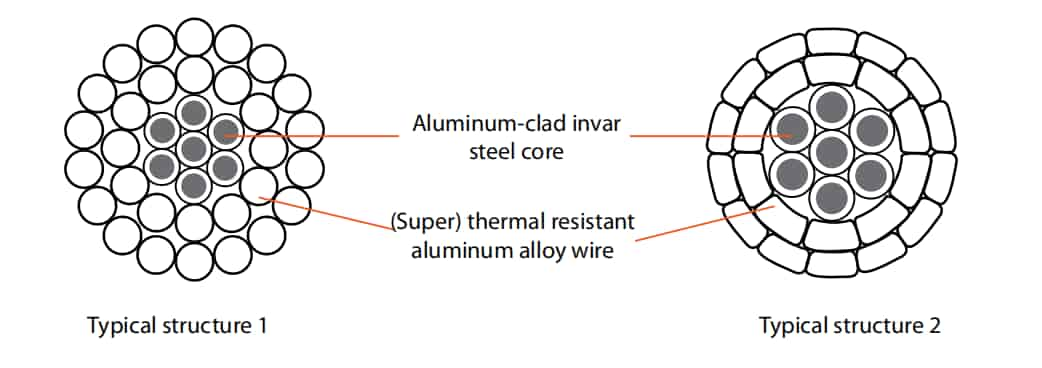

Composite Design

The conductor typically features a central Invar core wire or stranded Invar core, around which aluminum wires are helically wrapped. Depending on design requirements, the aluminum may be:

- Pure electrical-grade aluminum

- Heat-resistant aluminum alloy

- Aluminum-clad Invar wire (for enhanced corrosion protection)

Strand Configuration

Common strand arrangements include:

- Single Invar core with multiple aluminum layers

- Multi-wire Invar core combined with aluminum outer strands

- Custom strand constructions for specific voltage and span requirements

This flexible design approach allows manufacturers to tailor the conductor for different mechanical and electrical performance targets.

Working Principle: How Aluminum Clad Invar Cable Reduces Sag

Thermal sag is a major concern in overhead power lines. As current increases, conductor temperature rises, leading to expansion and increased sag. Excessive sag can compromise safety clearances and line reliability.

Thermal Behavior of Invar Core

The Invar core exhibits minimal thermal expansion, even at elevated temperatures. As a result:

- The core retains its original length more effectively

- Mechanical tension remains stable

- Sag growth is significantly reduced

Load Distribution

At higher operating temperatures, most of the mechanical load is transferred to the Invar core, while the aluminum primarily serves as a conductive layer. This separation of functions ensures stable performance under both electrical and mechanical stress.

Advantages of Aluminum Clad Invar Cable Conductor Wire

1. Excellent Low-Sag Performance

Thanks to the Invar core, this conductor maintains low sag across a wide temperature range, making it ideal for long-span and high-clearance applications.

2. High Mechanical Strength

The Invar alloy provides superior tensile strength compared to conventional steel cores, enabling higher stringing tensions and longer spans.

3. Increased Transmission Capacity

By allowing higher operating temperatures without excessive sag, aluminum clad Invar conductors can carry more current on existing transmission lines.

4. Long-Term Dimensional Stability

Low thermal expansion and high elastic modulus contribute to consistent performance over decades of service.

5. Reduced Infrastructure Modification

In reconductoring projects, these conductors often eliminate the need to replace towers or foundations, reducing project cost and downtime.

Typical Applications

Aluminum clad Invar cable conductor wire is widely used in:

- High-voltage and extra-high-voltage overhead transmission lines

- Grid upgrade and reconductoring projects

- Long river crossings and valley spans

- Urban transmission corridors with limited right-of-way

- Regions with high ambient temperatures

Its performance advantages make it a reliable choice for both new installations and system upgrades.

Comparison with Conventional Conductors

Aluminum Clad Invar vs ACSR

Compared with aluminum conductor steel-reinforced (ACSR) cables:

- Aluminum clad Invar conductors show much lower thermal expansion

- Sag performance is significantly improved

- Operating temperature limits are higher

- Long-term creep behavior is more stable

Aluminum Clad Invar vs Aluminum Alloy Core Conductors

While aluminum alloy core conductors offer weight reduction, Invar-based conductors excel in applications where dimensional stability and sag control are the primary concerns.

Manufacturing Process Overview

Producing aluminum clad Invar cable conductor wire requires precise control at every stage.

Invar Core Production

- Alloy composition control (iron–nickel ratio)

- Heat treatment to stabilize microstructure

- Mechanical testing for tensile and elastic properties

Aluminum Wire Preparation

- Drawing of aluminum or aluminum alloy wires

- Surface treatment to ensure smooth stranding

- Quality checks for conductivity and diameter

Stranding and Assembly

- Controlled stranding around the Invar core

- Accurate lay length and tension control

- Final dimensional and electrical inspection

Quality assurance ensures the conductor meets international performance requirements.

Standards and Compliance

Aluminum clad Invar conductors are commonly manufactured in accordance with:

- IEC standards for overhead line conductors

- ASTM standards for aluminum and alloy materials

- National grid specifications and project-specific requirements

Manufacturers typically provide full documentation, including mechanical test reports and electrical performance data.

Design Flexibility and Customization

One of the strengths of aluminum clad Invar cable conductor wire is its adaptability. Parameters that can be customized include:

- Aluminum cross-sectional area

- Invar core diameter and construction

- Strand configuration and lay length

- Maximum operating temperature

This flexibility allows engineers to optimize conductor design for specific environmental and mechanical conditions.

Installation and Handling Considerations

Although aluminum clad Invar conductors are compatible with standard overhead line hardware, proper handling is essential:

- Use appropriate stringing tension to protect the aluminum layers

- Follow manufacturer recommendations for clamps and fittings

- Consider sag–tension calculations specific to Invar core behavior

Correct installation ensures the conductor achieves its full performance potential.

Market Outlook and Future Development

As power grids continue to expand and modernize, demand for low thermal expansion conductors is expected to grow. Aluminum clad Invar cable conductor wire is well positioned to meet this demand due to its proven performance and long service life.

Future developments may include:

- Hybrid Invar-composite conductors

- Optimized aluminum alloys for higher efficiency

- Application in ultra-high-voltage transmission systems

Aluminum Clad Invar Cable Conductor Wire

Aluminum Clad Invar Cable Conductor Wire(HTLS Conductor) offers a reliable and efficient solution for overhead transmission systems that require low sag, high mechanical strength, and long-term stability. By combining the conductivity of aluminum with the dimensional stability of Invar alloy, this conductor meets the challenges of modern power transmission.

For utilities, EPC contractors, and grid operators seeking to increase capacity without extensive infrastructure changes, aluminum clad Invar conductors provide a practical and future-proof option.