Introduction

In modern power transmission systems, reliability and continuity of high-voltage cables are critical to ensuring stable electricity supply. Among the most important accessories in extra-high voltage (EHV) cable systems are 230kV cable straight joint splices, which are used to connect two cable sections in a straight-through configuration. These joints must withstand high electrical stress, thermal cycles, and harsh environmental conditions over decades of operation.

A 230kV cable straight joint splice is not merely a mechanical connection. It is a highly engineered insulation and stress-control system designed to restore the electrical, thermal, and mechanical integrity of the cable to a level equivalent to or better than the original cable insulation. As transmission voltages increase, the performance requirements for straight joint splices become increasingly stringent.

What Is a 230kV Cable Straight Joint Splice?

A 230kV cable straight joint splice (also known as a 230kV straight through cable joint or 230kV HV cable joint) is a cable accessory designed to connect two lengths of high-voltage power cable in a straight line without changing the direction of the circuit.

These joints are commonly used in:

- Underground transmission networks

- Substation interconnections

- Power plant outgoing feeders

- Long-distance EHV cable routes

In practical projects, cable lengths are limited by manufacturing, transportation, and installation constraints. Therefore, straight joint splices for 230kV cables are essential to extend cable routes while maintaining electrical continuity and insulation integrity.

Applications of 230kV High Voltage Cable Straight Joints

Underground Transmission Systems

Most 230kV XLPE cable straight joint splices are installed in underground cable systems where overhead lines are not feasible due to urban density, environmental restrictions, or aesthetic considerations.

Power Plants and Substations

In substations and power plants, 230kV cable jointing systems are used to connect outgoing or incoming cable sections between transformers, GIS equipment, and transmission corridors.

Industrial and Infrastructure Projects

Large industrial facilities, metro systems, data centers, and infrastructure projects rely on 230kV straight joint splices to ensure uninterrupted power delivery over long distances.

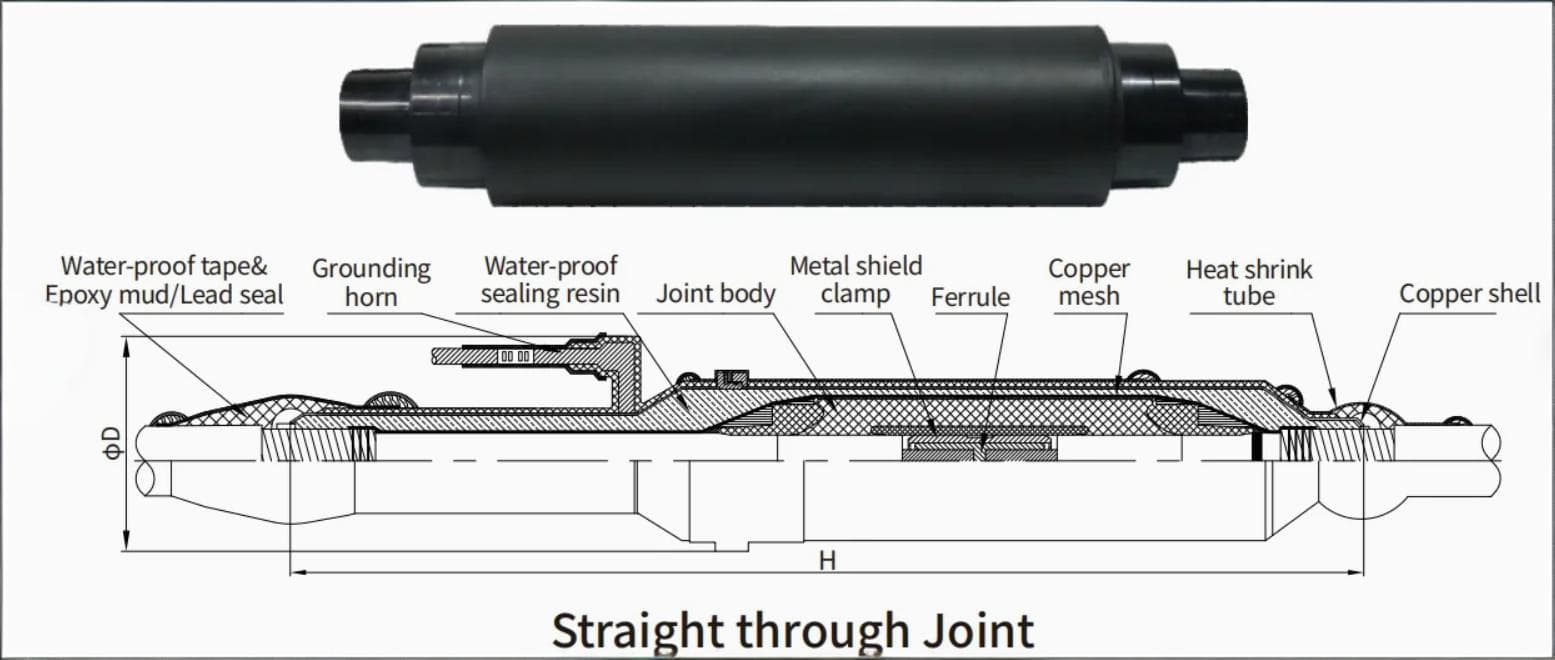

Structure of a 230kV Cable Straight Joint Splice

A typical 230kV cable straight joint splice consists of several precisely engineered layers, each serving a specific electrical or mechanical function.

1. Conductor Connector

The conductor connector ensures low-resistance electrical continuity between cable conductors. For 230kV applications, it is usually:

- Made of high-conductivity copper or aluminum

- Crimped or bolted, depending on joint design

- Designed to match conductor cross-section and material

2. Stress Control System

At 230kV, electrical stress concentration at the conductor screen cutback is a critical issue. Stress control is achieved using:

- Pre-molded stress cones

- Stress grading tapes

- Silicone or EPDM stress control components

These elements redistribute the electric field smoothly, preventing partial discharge and insulation failure.

3. Main Insulation Layer

The main insulation restores the dielectric strength of the cable. In 230kV XLPE cable straight joints, this layer typically uses:

- Cross-linked polyethylene (XLPE) compatible materials

- Pre-molded rubber or silicone insulation

- Factory-tested insulation systems

4. Metallic Shield and Screen Continuity

To maintain electromagnetic shielding and grounding:

- Copper wire screens or tapes are reconnected

- Metallic sleeves or braids ensure continuity

- Grounding leads are securely bonded

5. Outer Protective Sheath

The outer layer protects the joint from:

- Moisture ingress

- Mechanical damage

- Chemical corrosion

This sheath is often made of heat-shrinkable or cold-shrinkable materials with excellent sealing properties.

Types of 230kV Cable Straight Joint Splices

Pre-Molded Straight Joints

Pre-molded 230kV straight through joints are factory-manufactured with precise dimensions and material properties. Advantages include:

- Consistent quality

- Shorter installation time

- Lower risk of installation errors

Heat Shrink Straight Joints

Heat shrink 230kV cable joint splices use specially formulated materials that shrink under heat to form a tight seal. They offer flexibility but require skilled installation.

Cold Shrink Straight Joints

Cold shrink joints are increasingly popular for 230kV high voltage cable jointing due to:

- No need for open flame

- Uniform radial pressure

- Reliable long-term performance

Installation Process of 230kV Cable Straight Joint Splices

Proper installation is critical to the performance of any 230kV cable straight joint splice. Even the best-designed joint can fail if installed incorrectly.

Step 1: Cable Preparation

- Precise removal of outer sheath, armor, and insulation

- Accurate conductor and screen cutback dimensions

- Thorough cleaning of insulation surface

Step 2: Conductor Connection

- Installation of compression or bolted connector

- Verification of correct crimping force

- Measurement of contact resistance

Step 3: Stress Control Application

- Installation of stress grading components

- Ensuring smooth transition between layers

- Avoidance of air gaps or sharp edges

Step 4: Insulation and Shielding

- Placement of main insulation body

- Restoration of metallic screen continuity

- Proper grounding of shield components

Step 5: Outer Sealing and Protection

- Application of outer sheath

- Moisture sealing and mechanical reinforcement

- Final inspection and documentation

Standards and Testing for 230kV Cable Straight Joints

High-voltage cable accessories must comply with international standards to ensure safety and performance.

Common Standards

- IEC 60840 (Power cables above 30 kV)

- IEC 62067 (EHV cable systems above 150 kV)

- IEEE 404 / IEEE 48

- CIGRÉ recommendations

Routine and Type Tests

A 230kV cable straight joint splice typically undergoes:

- Partial discharge testing

- AC voltage withstand tests

- Lightning impulse tests

- Thermal cycling tests

- Long-term aging simulations

These tests confirm that the joint performs reliably under real operating conditions.

Performance and Reliability Considerations

Electrical Performance

A properly installed 230kV high voltage cable straight joint should exhibit:

- No partial discharge at rated voltage

- Stable dielectric properties over time

- Uniform electric field distribution

Thermal Performance

- Ability to handle rated current continuously

- Resistance to thermal expansion and contraction

- Long-term stability under load cycling

Mechanical and Environmental Resistance

- Vibration and ground movement tolerance

- Moisture and chemical resistance

- Long service life, typically 30–40 years

Common Causes of Failure in 230kV Cable Straight Joint Splices

Despite advanced designs, failures can occur due to:

- Improper cable preparation

- Incorrect stress control installation

- Contamination of insulation surfaces

- Poor grounding or screen connection

These risks highlight the importance of trained installers and strict quality control in 230kV cable jointing systems.

Advantages of High-Quality 230kV Cable Straight Joints

Using well-designed and tested 230kV cable straight joint splices offers several benefits:

- Enhanced system reliability

- Reduced maintenance costs

- Lower risk of unplanned outages

- Improved safety for operators and infrastructure

In large-scale transmission projects, the cost of a high-quality joint is minimal compared to the potential losses caused by joint failure.

Future Trends in 230kV Cable Joint Technology

The development of 230kV cable straight joint splices continues to evolve, focusing on:

- Advanced silicone rubber materials

- Improved stress grading techniques

- Smart monitoring systems for joint condition

- Environmentally friendly and recyclable materials

As power networks expand and urbanization increases, demand for reliable 230kV high voltage cable straight joints will continue to grow.

230kV cable straight joint splice

A 230kV cable straight joint splice is a critical component in high-voltage power transmission systems. It plays a vital role in ensuring electrical continuity, insulation integrity, and long-term reliability of 230kV cable networks. From conductor connection and stress control to insulation restoration and environmental protection, every element of the joint must be carefully designed and installed.

By selecting high-quality 230kV straight through cable joints, adhering to international standards, and following rigorous installation procedures, utilities and contractors can significantly enhance the performance and lifespan of their high-voltage cable systems. In an era where power reliability is more important than ever, the importance of robust and well-engineered 230kV cable straight joint splices cannot be overstated.

Please contact us price, Your 230kV Cable Straight Joint kits Manufacturer.