Introduction

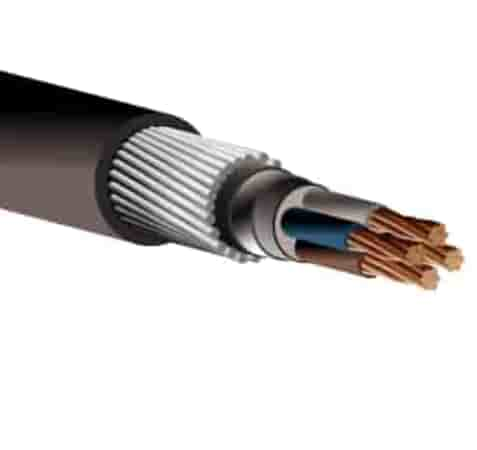

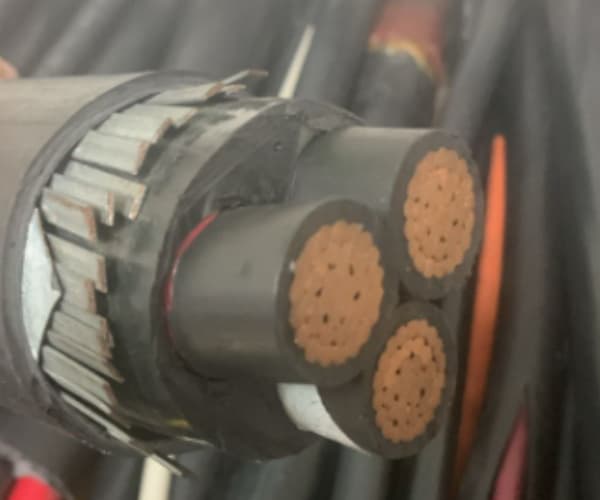

The CU/MGT/XLPE/LS/SFA/PVC-FR 0.6/1 (1.2) kV FR Cable is a high-performance, fire-resistant, armoured low-voltage power cable designed for critical power distribution systems. This cable combines electrical reliability, fire survival capability, mechanical protection, and environmental resistance, making it suitable for demanding industrial and infrastructure applications.

With a construction consisting of Copper Conductor (CU), Mica Glass Tape (MGT), XLPE insulation, Lead Sheath (LS), Steel Flat Armour (SFA), and a Flame Retardant PVC outer sheath, this cable is engineered to maintain circuit integrity even under severe fire and mechanical stress conditions.

The rated voltage of 0.6/1 (1.2) kV makes it ideal for low-voltage power transmission where safety, durability, and long service life are mandatory.

Meaning of CU/MGT/XLPE/LS/SFA/PVC-FR

The designation CU/MGT/XLPE/LS/SFA/PVC-FR 0.6/1 (1.2) kV clearly describes the cable structure from the conductor outward:

- CU – Copper Conductor

High-purity annealed copper conductor manufactured in accordance with IEC standards. - MGT – Mica Glass Tape

Fire-resistant tape applied over the conductor or insulation to maintain electrical integrity during fire. - XLPE – Cross-Linked Polyethylene Insulation

High-performance insulation material with excellent dielectric and thermal properties. - LS – Lead Sheath

A continuous metallic sheath providing moisture, chemical, and corrosion protection. - SFA – Steel Flat Armour

Mechanical armour offering high resistance to impact, compression, and external forces. - PVC-FR – Flame Retardant PVC Outer Sheath

Final protective layer with enhanced flame-retardant performance.

This multilayer structure makes the cable particularly suitable for underground installations, tunnels, power plants, oil & gas facilities, refineries, substations, and emergency power circuits.

General Cable Construction

A typical CU/MGT/XLPE/LS/SFA/PVC-FR 0.6/1 (1.2) kV FR Cable consists of the following layers:

- Copper conductor (IEC 60228)

- Mica glass tape fire barrier

- XLPE insulation

- Laid-up cores with fillers (for multi-core cables)

- Lead sheath (LS)

- PVC separator / bedding

- Steel flat armour (SFA)

- Flame retardant PVC outer sheath (PVC-FR)

Each layer serves a specific electrical, thermal, mechanical, or protective function.

Copper Conductor (CU)

The conductor is made of annealed electrolytic copper with high conductivity and excellent mechanical strength. Conductors are manufactured in accordance with IEC 60228, typically as:

- Class 1 – Solid conductor (mainly for small cross-sections)

- Class 2 – Stranded conductor (most common for power cables)

Copper conductors ensure:

- Low conductor resistance

- High current-carrying capacity

- Excellent thermal stability

- Long service life

Mica Glass Tape (MGT) – Fire Resistance Layer

The mica glass tape layer is the key component that gives the cable its fire-resistant (FR) capability.

Main characteristics:

- Maintains insulation integrity under direct flame

- Withstands temperatures up to 750–950°C

- Prevents short circuits during fire exposure

- Enables circuit operation for emergency systems

This layer is essential for compliance with fire survival requirements in critical installations.

XLPE Insulation

XLPE insulation is applied over the conductor or MGT layer.

Key advantages:

- Rated operating temperature: 90°C

- Short-circuit temperature: 250°C

- High dielectric strength

- Excellent resistance to moisture, chemicals, and aging

XLPE insulation ensures reliable power transmission even in harsh environments.

Lead Sheath (LS)

The Lead Sheath (LS) is a continuous extruded metallic layer applied over the laid-up insulated cores.

Functions of Lead Sheath

- Excellent moisture barrier

- High resistance to oils, chemicals, and corrosive substances

- Protection against water ingress

- Enhanced electromagnetic shielding

Because of these properties, LS cables are widely used in underground, industrial, and chemically aggressive environments.

Steel Flat Armour (SFA)

The Steel Flat Armour (SFA) provides strong mechanical protection.

Advantages:

- High resistance to impact and crushing

- Suitable for direct burial

- Improved tensile strength

- Protection against rodent damage

SFA makes the cable suitable for heavy-duty installations where mechanical stress is expected.

PVC-FR Outer Sheath

The final layer is a Flame Retardant PVC (PVC-FR) outer sheath.

Functions:

- Flame retardancy

- UV resistance

- Protection against abrasion and weather

- Easy identification and installation

IEC Conductor Construction – 1 Core to 5 Cores (0.5 mm² to 300 mm²)

IEC Conductor Structure Table (0.5–300 mm², 1C–5C)

| Nominal Cross Section (mm²) | Conductor Class | No. of Cores | Conductor Construction (IEC 60228) |

|---|---|---|---|

| 0.5 | Class 1 | 1–5 | – |

| 0.75 | Class 1 | 1–5 | – |

| 1.0 | Class 1 | 1–5 | – |

| 1.5 | Class 2 | 1–5 | 7 × 0.52 mm |

| 2.5 | Class 2 | 1–5 | 7 × 0.67 mm |

| 4 | Class 2 | 1–5 | 7 × 0.85 mm |

| 6 | Class 2 | 1–5 | 7 × 1.04 mm |

| 10 | Class 2 | 1–5 | 7 × 1.35 mm |

| 16 | Class 2 | 1–5 | 7 × 1.70 mm |

| 25 | Class 2 | 1–5 | 7 × 2.14 mm |

| 35 | Class 2 | 1–5 | 7 × 2.52 mm |

| 50 | Class 2 | 1–5 | 19 × 1.78 mm |

| 70 | Class 2 | 1–5 | 19 × 2.14 mm |

| 95 | Class 2 | 1–5 | 19 × 2.52 mm |

| 120 | Class 2 | 1–5 | 37 × 2.03 mm |

| 150 | Class 2 | 1–5 | 37 × 2.25 mm |

| 185 | Class 2 | 1–5 | 37 × 2.52 mm |

| 240 | Class 2 | 1–5 | 61 × 2.25 mm |

| 300 | Class 2 | 1–5 | 61 × 2.52 mm |

IEC Conductor Construction – 1 Core to 36 Cores (0.5 mm² to 10 mm²)

IEC Multi-Core Conductor Structure Table (0.5–10 mm², 1C–36C)

| Nominal Cross Section (mm²) | Conductor Class | No. of Cores | Typical IEC Construction |

|---|---|---|---|

| 0.5 | Class 1 | 1–36 | – |

| 0.75 | Class 1 | 1–36 | – |

| 1.0 | Class 1 | 1–36 | – |

| 1.5 | Class 2 | 1–36 | 7 × 0.52 mm |

| 2.5 | Class 2 | 1–36 | 7 × 0.67 mm |

| 4 | Class 2 | 1–36 | 7 × 0.85 mm |

| 6 | Class 2 | 1–36 | 7 × 1.04 mm |

| 10 | Class 2 | 1–36 | 7 × 1.35 mm |

These configurations are widely used in control cables, power distribution panels, emergency circuits, and instrumentation systems.

Applications

The CU/MGT/XLPE/LS/SFA/PVC-FR 0.6/1 (1.2) kV FR Cable is suitable for:

- Power plants and substations

- Tunnels and metro systems

- Oil & gas and petrochemical plants

- Industrial facilities

- Underground and direct burial installations

- Emergency and fire survival circuits

Key Advantages

- Excellent fire resistance

- Strong mechanical protection

- Superior moisture and chemical resistance

- Long service life

- IEC-compliant conductor construction

- Suitable for harsh and critical environments

CU/MGT/XLPE/LS/SFA/PVC-FR 0.6/1 (1.2) kV FR Cable

The CU/MGT/XLPE/LS/SFA/PVC-FR 0.6/1 (1.2) kV FR Cable represents a robust and reliable solution for low-voltage power distribution where fire safety, mechanical strength, and environmental protection are critical. With a carefully engineered structure and standardized IEC conductor configurations, this cable meets the highest expectations of modern electrical and industrial projects.