Introduzione

IL N2XKFGbY (CU/XLPE/PVC/LS/PVC/SFWA/PVC) 0.6/1 (1.2) kV cable is a robust low-voltage power cable designed for applications requiring high mechanical protection, moisture resistance, and long-term electrical reliability. With its multi-layer construction and armoured design, this cable is widely used in impianti industriali, power distribution networks, underground installations, and infrastructure projects.

The designation N2XKFGbY follows European and IEC-based cable naming conventions and represents a cable system that combines copper conductors, Isolamento XLPE, a lead sheath (LS), steel flat armour (SFA), and multiple PVC protective layers. The rated voltage of 0.6/1 (1.2) kV makes it suitable for low-voltage power transmission under demanding environmental and mechanical conditions.

Meaning of N2XKFGbY (CU/XLPE/PVC/LS/PVC/SFWA/PVC)

The structure of the N2XKFGbY cable can be clearly understood by breaking down its material designation:

- CU – Copper conductor

- XLPE – Cross-linked polyethylene insulation

- PVC – Polyvinyl chloride inner sheath and bedding layers

- LS – Lead Sheath

- PVC – Separator / bedding sheath over the lead sheath

- SFA – Steel Flat Armour

- PVC – PVC outer sheath

Insieme, this construction delivers a cable with excellent electrical performance, strong mechanical protection, and superior resistance to moisture and aggressive environments.

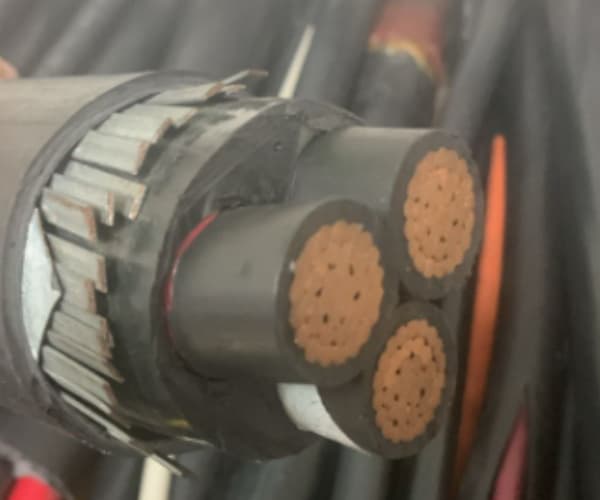

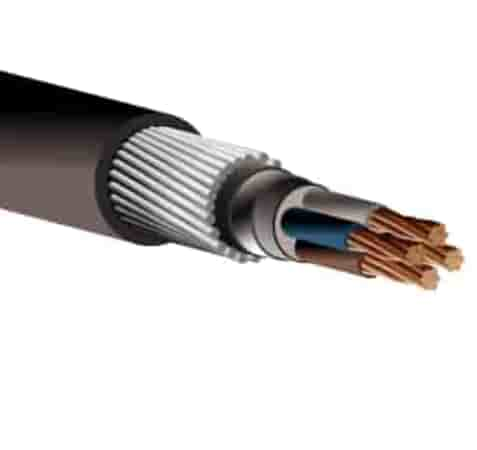

General Cable Construction

Un tipico N2XKFGbY (CU/XLPE/PVC/LS/PVC/SFWA/PVC) 0.6/1 (1.2) kV cable consists of the following layers from inside to outside:

- Copper conductor (IEC compliant)

- Isolamento XLPE

- Laid-up insulated cores with fillers

- PVC inner sheath

- Guaina di piombo (LS)

- PVC separator / bedding

- Steel flat armour (SFA)

- PVC outer sheath

Each layer is carefully engineered to serve a specific electrical or mechanical function.

Copper Conductor (CU)

The conductor is made of high-purity annealed electrolytic copper, offering excellent conductivity and mechanical stability. All conductors comply with CEI 60228, typically manufactured as:

- Class 1 solid conductors (for smaller cross-sections)

- Class 2 stranded conductors (for power applications)

Copper conductors ensure:

- Low electrical resistance

- High current-carrying capacity

- Stable performance under thermal stress

- Long operational life

XLPE Insulation

Each copper conductor is insulated with cross-linked polyethylene (XLPE), a material widely recognized for its superior electrical and thermal performance.

Key properties of XLPE insulation include:

- Continuous operating temperature up to 90°C

- Short-circuit temperature up to 250°C

- High dielectric strength

- Excellent resistance to moisture, prodotti chimici, and aging

XLPE insulation ensures safe and reliable power transmission even in harsh operating environments.

PVC Inner Sheath

After core assembly, a PVC inner sheath is applied to bind the insulated conductors together and provide a smooth surface for the application of the lead sheath.

Functions of the PVC inner sheath:

- Maintains cable geometry

- Protects insulated cores

- Improves mechanical stability

- Enhances overall durability

Lead Sheath (LS)

IL Lead Sheath (LS) is one of the most critical features of the N2XKFGbY cable.

Functions of the Lead Sheath

- Acts as a complete moisture barrier

- Provides excellent resistance to oils, prodotti chimici, and corrosive substances

- Prevents water ingress in underground installations

- Enhances electromagnetic shielding

Because of these properties, lead-sheathed cables are widely used in underground power networks, industrial facilities, tunnels, and areas with high humidity or chemical exposure.

PVC Separator / Bedding Sheath

A PVC separator sheath is applied over the lead sheath to:

- Protect the lead sheath from mechanical damage

- Provide a smooth bedding for the armour layer

- Improve overall cable flexibility

This layer also contributes to the long-term stability of the cable under mechanical stress.

Steel Flat Armour (SFA)

IL Steel Flat Armour (SFA) provides strong mechanical protection against external forces.

Advantages of SFA include:

- High resistance to impact and crushing

- Excellent tensile strength

- Suitable for direct burial

- Protection against rodent damage

Steel flat armour makes the cable suitable for heavy-duty industrial and infrastructure installations.

PVC Outer Sheath

The final layer is a durable PVC outer sheath, designed to protect the cable from environmental influences.

Key features:

- Resistance to abrasion and mechanical wear

- Protection against UV radiation and weather

- Additional moisture resistance

- Easy identification and handling

Rated Voltage: 0.6/1 (1.2) kV

The rated voltage 0.6/1 (1.2) kV indicates:

- 0.6 kV between conductor and earth

- 1.0 kV between conductors

- 1.2 kV maximum system voltage

This rating makes the cable suitable for standard low-voltage power distribution systems.

IEC Conductor Configuration – 1 Core to 5 Cores (0.5 mm² a 300 mm²)

IEC Power Cable Conductor Configuration

| Nominal Cross Section (mm²) | Conductor Class | NO. of Cores |

|---|---|---|

| 0.5 | Class 1 | 1 core |

| 0.5 | Class 1 | 2 cores |

| 0.5 | Class 1 | 3 cores |

| 0.5 | Class 1 | 4 cores |

| 0.5 | Class 1 | 5 cores |

| 0.75 | Class 1 | 1–5 cores |

| 1.0 | Class 1 | 1–5 cores |

| 1.5 | Class 2 | 1–5 cores |

| 2.5 | Class 2 | 1–5 cores |

| 4 | Class 2 | 1–5 cores |

| 6 | Class 2 | 1–5 cores |

| 10 | Class 2 | 1–5 cores |

| 16 | Class 2 | 1–5 cores |

| 25 | Class 2 | 1–5 cores |

| 35 | Class 2 | 1–5 cores |

| 50 | Class 2 | 1–5 cores |

| 70 | Class 2 | 1–5 cores |

| 95 | Class 2 | 1–5 cores |

| 120 | Class 2 | 1–5 cores |

| 150 | Class 2 | 1–5 cores |

| 185 | Class 2 | 1–5 cores |

| 240 | Class 2 | 1–5 cores |

| 300 | Class 2 | 1–5 cores |

IEC Conductor Configuration – 1 Core to 36 Cores (0.5 mm² a 10 mm²)

IEC Multi-Core Cable Configuration

| Nominal Cross Section (mm²) | Conductor Class | NO. of Cores |

|---|---|---|

| 0.5 | Class 1 | 1–36 cores |

| 0.75 | Class 1 | 1–36 cores |

| 1.0 | Class 1 | 1–36 cores |

| 1.5 | Class 2 | 1–36 cores |

| 2.5 | Class 2 | 1–36 cores |

| 4 | Class 2 | 1–36 cores |

| 6 | Class 2 | 1–36 cores |

| 10 | Class 2 | 1–36 cores |

These configurations are commonly used for cavi di controllo, auxiliary power circuits, and industrial distribution systems.

Applicazioni tipiche

IL N2XKFGbY (CU/XLPE/PVC/LS/PVC/SFWA/PVC) 0.6/1 (1.2) kV cable is widely applied in:

- Power plants and substations

- Industrial manufacturing facilities

- Underground power distribution

- Tunnels and transportation infrastructure

- Oil, gas, and petrochemical plants

- Utilities and public infrastructure projects

Key Advantages

- Excellent electrical performance

- Strong mechanical protection

- Superior moisture and chemical resistance

- Lunga durata

- IEC-compliant conductor configurations

- Suitable for harsh and underground environments

N2XKFGbY (CU/XLPE/PVC/LS/PVC/SFWA/PVC) 0.6/1 (1.2) kV cable

IL N2XKFGbY (CU/XLPE/PVC/LS/PVC/SFWA/PVC) 0.6/1 (1.2) kV cable is a proven solution for low-voltage power transmission where resistenza meccanica, protezione dell'ambiente, and long-term reliability are essential. With its lead sheath and steel flat armour design, this cable meets the demands of modern industrial and infrastructure applications.