Introduzione: The Strategic Importance of Submarine Power Cable

In the modern energy era, l’elettricità non scorre più solo attraverso la terra. Viaggia sotto gli oceani, mari, fiumi, e laghi, paesi che collegano, islands, offshore facilities, and renewable energy projects. At the heart of this invisible infrastructure lies the submarine power cable.

A submarine power cable is a critical component of global power transmission networks. It enables long-distance electricity transfer across water bodies, supports offshore wind farms, connects islands to mainland grids, and strengthens international energy cooperation. As energy demand grows and renewable energy expands offshore, submarine power cable systems have become more important than ever.

For professional cable manufacturers such as DUE FILI, submarine power cable technology represents not only engineering excellence but also a strategic contribution to global energy security. We explains what a submarine power cable is, come funziona, its structure, applicazioni, installation process, and why high-quality manufacturing is essential for long-term reliability.

Che cos'è il cavo di alimentazione sottomarino?

UN submarine power cable is a specially designed electrical cable used to transmit power underwater. It is installed beneath seas, oceans, fiumi, or lakes and is engineered to operate reliably under extreme environmental conditions, including water pressure, corrosione, sollecitazione meccanica, and temperature variation.

Unlike standard land-based power cables, a submarine power cable must provide:

- Excellent water resistance

- Strong mechanical protection

- Long-term electrical stability

- High insulation performance

Submarine power cables are widely used for underwater power transmission, connecting offshore and onshore power systems seamlessly.

Why Submarine Power Cable Is Essential in Modern Power Networks

Connecting Islands to Mainland Grids

Many islands rely on submarine power cables to receive stable electricity from mainland power grids. Compared with local diesel generation, submarine power cable systems offer:

- Lower operating costs

- Reduced environmental impact

- Improved power reliability

Supporting Offshore Renewable Energy

Offshore wind farms generate massive amounts of clean energy. UN submarine power cable is the only practical solution to transmit this energy from offshore turbines to onshore substations.

Cross-Border Power Transmission

Submarine power cables enable countries to share electricity across seas, improving grid stability and energy security.

Main Types of Submarine Power Cable

Low Voltage Submarine Power Cable

Low voltage submarine power cables are typically used for:

- Small islands

- Marine equipment

- Harbor facilities

These cables operate at voltages up to 1 kV and are designed for short-distance underwater applications.

Medium Voltage Submarine Power Cable

Medium voltage submarine power cables are widely used in:

- Offshore wind farms

- Industrial offshore platforms

- Coastal power transmission

Voltage ranges typically include 6 kV, 10 kV, 20 kV, E 35 kV.

High Voltage Submarine Power Cable

High voltage submarine power cables are used for long-distance and high-capacity power transmission. These cables are critical for:

- Intercontinental power links

- Large offshore renewable projects

- National power grids

High voltage submarine power cables often operate at 110 kV, 220 kV, or higher.

HVAC vs HVDC Submarine Power Cable

HVAC submarine power cable

- Used for shorter distances

- Simpler converter requirements

HVDC submarine power cable

- Ideal for long-distance transmission

- Lower energy losses

- Increasingly popular in modern projects

DOS CABLE provides customized submarine power cable solutions for both HVAC and HVDC systems.

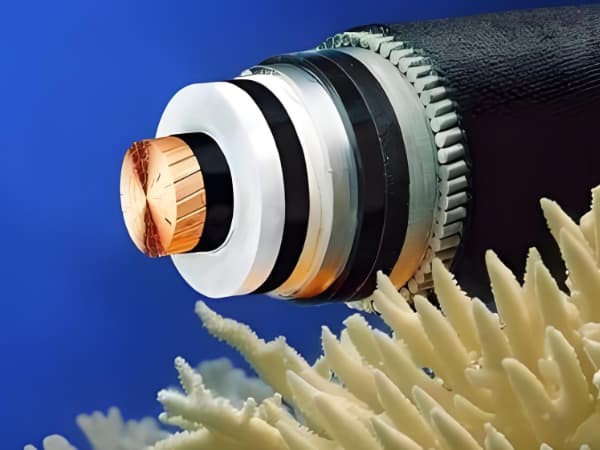

Structure of a Submarine Power Cable

A submarine power cable consists of multiple layers, each designed for a specific function.

Conduttore

The conductor is usually made of copper or aluminum. It carries the electrical current and must offer low resistance and high conductivity.

Insulation Layer

High-quality insulation is essential for electrical safety and long-term performance. Common materials include:

- XLPE (Polietilene Reticolato)

- Epr (Ethylene Propylene Rubber)

DOS CABLE uses advanced insulation technologies to ensure stable performance in harsh underwater environments.

Water Blocking Layer

Submarine power cables include water-blocking materials to prevent moisture penetration, which could damage the conductor or insulation.

Metallic Sheath

A metallic sheath, often made of lead or aluminum, provides additional water resistance and electrical shielding.

Armoring Layer

The armoring layer protects the submarine power cable from:

- Mechanical impact

- Fishing activities

- Anchors and seabed movement

Single or double steel wire armoring is commonly used depending on installation depth.

Outer Jacket

The outer jacket provides corrosion resistance and protects the cable from seawater and chemical exposure.

How Submarine Power Cable Works

A submarine power cable works by transmitting electrical energy from a source (such as a power plant or offshore wind farm) to a destination (such as an onshore grid). The cable is carefully laid on or buried beneath the seabed to ensure stability and protection.

Electricity flows through the conductor, while insulation and shielding layers prevent leakage and ensure safe operation. Proper design and manufacturing are crucial to minimize energy losses and extend service life.

Applications of Submarine Power Cable

Offshore Wind Power Transmission

Offshore wind farms depend entirely on submarine power cables to transmit electricity to land-based substations.

Oil and Gas Platforms

Submarine power cables supply electricity to offshore oil and gas platforms, reducing reliance on onboard generators.

Island Electrification Projects

Island electrification projects use submarine power cables to deliver stable power from mainland grids.

Interconnector Projects

Submarine power cables are essential for international interconnector projects, enabling power trading between countries.

Installation of Submarine Power Cable

Rilievo e pianificazione del percorso

Prima dell'installazione, detailed seabed surveys are conducted to assess:

- Condizioni del fondale marino

- Profondità dell'acqua

- Impatto ambientale

Cable Laying Process

Specialized cable-laying vessels are used to install submarine power cables. The cable may be:

- Laid directly on the seabed

- Buried using jetting or plowing techniques

Protection and Testing

After installation, the submarine power cable undergoes electrical testing to ensure proper performance and safety.

Challenges of Submarine Power Cable Systems

Harsh Marine Environment

Saltwater corrosion, pressure, and temperature variations present significant challenges for submarine power cables.

Mechanical Damage Risks

Fishing gear, ancore, and seabed movement can damage unprotected cables.

High Manufacturing Standards

Submarine power cable manufacturing requires strict quality control and advanced technology.

DOS CABLE applies rigorous testing and inspection procedures to ensure long-term reliability.

Advantages of High-Quality Submarine Power Cable from DOS CABLE

Lunga durata

Well-designed submarine power cables can operate reliably for decades.

Energy Efficiency

Low-resistance conductors and advanced insulation reduce energy losses.

Customization Capability

DOS CABLE provides customized submarine power cable solutions based on project requirements, voltage levels, and installation conditions.

Compliance with International Standards

High-quality submarine power cables meet international standards, ensuring compatibility with global power systems.

Quality Control in Submarine Power Cable Manufacturing

At DOS CABLE, submarine power cable production follows strict quality procedures, compreso:

- Raw material inspection

- Conductor resistance testing

- Insulation thickness measurement

- High-voltage testing

- Mechanical strength testing

These processes ensure that each submarine power cable delivers consistent performance in real-world applications.

Maintenance and Monitoring of Submarine Power Cable

Although submarine power cables are designed for long-term operation, monitoring systems are often used to:

- Detect faults early

- Reduce downtime

- Improve grid reliability

Proper maintenance planning extends the service life of submarine power cable systems.

Future Trends in Submarine Power Cable Technology

Growing Demand from Offshore Renewables

As offshore wind and marine energy projects expand, demand for submarine power cable solutions will continue to rise.

Higher Voltage and Capacity

Future submarine power cables will support higher voltages and greater transmission capacity.

Smarter Cable Systems

Advanced monitoring and diagnostic technologies will improve reliability and performance.

DOS CABLE continues to invest in innovation to meet these future demands.

Why Choose DOS CABLE for Submarine Power Cable Solutions

DOS CABLE is committed to delivering reliable, high-performance submarine power cable solutions for global customers. With advanced manufacturing capabilities, rigoroso controllo di qualità, and strong technical expertise, DOS CABLE supports projects ranging from offshore renewable energy to island electrification and cross-border power transmission.

By choosing a professional manufacturer like DOS CABLE, customers gain access to durable, efficiente, and customized submarine power cable systems designed for long-term success.

Understanding What Submarine Power Cable Is and Why It Matters

COSÌ, what is submarine power cable? It is far more than just an underwater wire. A submarine power cable is a vital link in the global energy network, enabling electricity transmission across water, supporting renewable energy, and connecting communities worldwide.

As energy systems evolve, the role of submarine power cable technology will continue to expand. With experienced manufacturers like DUE FILI, businesses and governments can rely on safe, efficiente, and future-ready submarine power cable solutions.