Pengenalan

The N2XKFGbY (CU/XLPE/PVC/LS/PVC/SFWA/PVC) 0.6/1 (1.2) kabel kV is a robust low-voltage power cable designed for applications requiring high mechanical protection, moisture resistance, and long-term electrical reliability. With its multi-layer construction and armoured design, this cable is widely used in loji industri, power distribution networks, underground installations, and infrastructure projects.

The designation N2XKFGbY follows European and IEC-based cable naming conventions and represents a cable system that combines copper conductors, penebat XLPE, a lead sheath (LS), steel flat armour (SFA), and multiple PVC protective layers. The rated voltage of 0.6/1 (1.2) kV makes it suitable for low-voltage power transmission under demanding environmental and mechanical conditions.

Meaning of N2XKFGbY (CU/XLPE/PVC/LS/PVC/SFWA/PVC)

The structure of the N2XKFGbY cable can be clearly understood by breaking down its material designation:

- CU – Copper conductor

- XLPE – Cross-linked polyethylene insulation

- PVC – Polyvinyl chloride inner sheath and bedding layers

- LS – Lead Sheath

- PVC – Separator / bedding sheath over the lead sheath

- SFA – Steel Flat Armour

- PVC – PVC outer sheath

Together, this construction delivers a cable with excellent electrical performance, strong mechanical protection, and superior resistance to moisture and aggressive environments.

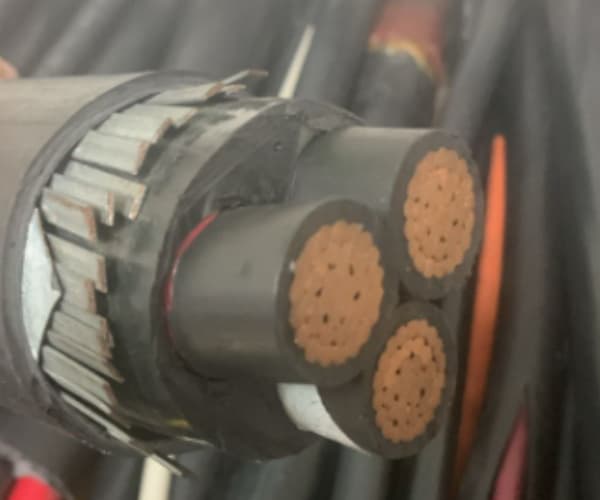

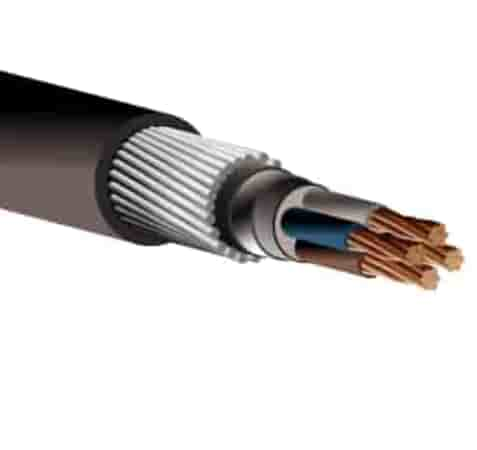

General Cable Construction

Satu tipikal N2XKFGbY (CU/XLPE/PVC/LS/PVC/SFWA/PVC) 0.6/1 (1.2) kabel kV consists of the following layers from inside to outside:

- Copper conductor (IEC compliant)

- penebat XLPE

- Laid-up insulated cores with fillers

- PVC inner sheath

- Sarung plumbum (LS)

- PVC separator / bedding

- Steel flat armour (SFA)

- PVC outer sheath

Each layer is carefully engineered to serve a specific electrical or mechanical function.

Copper Conductor (CU)

The conductor is made of high-purity annealed electrolytic copper, offering excellent conductivity and mechanical stability. All conductors comply with IEC 60228, typically manufactured as:

- Kelas 1 solid conductors (for smaller cross-sections)

- Kelas 2 stranded conductors (for power applications)

Copper conductors ensure:

- Low electrical resistance

- High current-carrying capacity

- Stable performance under thermal stress

- Long operational life

XLPE Insulation

Each copper conductor is insulated with cross-linked polyethylene (XLPE), a material widely recognized for its superior electrical and thermal performance.

Key properties of XLPE insulation include:

- Continuous operating temperature up to 90°C

- Short-circuit temperature up to 250°C

- High dielectric strength

- Excellent resistance to moisture, bahan kimia, and aging

XLPE insulation ensures safe and reliable power transmission even in harsh operating environments.

PVC Inner Sheath

After core assembly, a PVC inner sheath is applied to bind the insulated conductors together and provide a smooth surface for the application of the lead sheath.

Functions of the PVC inner sheath:

- Maintains cable geometry

- Protects insulated cores

- Improves mechanical stability

- Enhances overall durability

Lead Sarung (LS)

The Lead Sarung (LS) is one of the most critical features of the N2XKFGbY cable.

Functions of the Lead Sheath

- Acts as a complete moisture barrier

- Provides excellent resistance to oils, bahan kimia, and corrosive substances

- Prevents water ingress in underground installations

- Enhances electromagnetic shielding

Because of these properties, lead-sheathed cables are widely used in underground power networks, industrial facilities, tunnels, and areas with high humidity or chemical exposure.

PVC Separator / Bedding Sheath

A PVC separator sheath is applied over the lead sheath to:

- Protect the lead sheath from mechanical damage

- Provide a smooth bedding for the armour layer

- Improve overall cable flexibility

This layer also contributes to the long-term stability of the cable under mechanical stress.

Steel Flat Armour (SFA)

The Steel Flat Armour (SFA) provides strong mechanical protection against external forces.

Advantages of SFA include:

- High resistance to impact and crushing

- Excellent tensile strength

- Suitable for direct burial

- Protection against rodent damage

Steel flat armour makes the cable suitable for heavy-duty industrial and infrastructure installations.

PVC Outer Sheath

The final layer is a durable PVC outer sheath, designed to protect the cable from environmental influences.

Key features:

- Resistance to abrasion and mechanical wear

- Protection against UV radiation and weather

- Additional moisture resistance

- Easy identification and handling

Rated Voltage: 0.6/1 (1.2) kV

The rated voltage 0.6/1 (1.2) kV indicates:

- 0.6 kV between conductor and earth

- 1.0 kV between conductors

- 1.2 kV maximum system voltage

This rating makes the cable suitable for standard low-voltage power distribution systems.

IEC Conductor Configuration – 1 Core to 5 Cores (0.5 mm² kepada 300 mm²)

IEC Power Cable Conductor Configuration

| Nominal Cross Section (mm²) | Conductor Class | Tidak. of Cores |

|---|---|---|

| 0.5 | Kelas 1 | 1 core |

| 0.5 | Kelas 1 | 2 cores |

| 0.5 | Kelas 1 | 3 cores |

| 0.5 | Kelas 1 | 4 cores |

| 0.5 | Kelas 1 | 5 cores |

| 0.75 | Kelas 1 | 1–5 cores |

| 1.0 | Kelas 1 | 1–5 cores |

| 1.5 | Kelas 2 | 1–5 cores |

| 2.5 | Kelas 2 | 1–5 cores |

| 4 | Kelas 2 | 1–5 cores |

| 6 | Kelas 2 | 1–5 cores |

| 10 | Kelas 2 | 1–5 cores |

| 16 | Kelas 2 | 1–5 cores |

| 25 | Kelas 2 | 1–5 cores |

| 35 | Kelas 2 | 1–5 cores |

| 50 | Kelas 2 | 1–5 cores |

| 70 | Kelas 2 | 1–5 cores |

| 95 | Kelas 2 | 1–5 cores |

| 120 | Kelas 2 | 1–5 cores |

| 150 | Kelas 2 | 1–5 cores |

| 185 | Kelas 2 | 1–5 cores |

| 240 | Kelas 2 | 1–5 cores |

| 300 | Kelas 2 | 1–5 cores |

IEC Conductor Configuration – 1 Core to 36 Cores (0.5 mm² kepada 10 mm²)

IEC Multi-Core Cable Configuration

| Nominal Cross Section (mm²) | Conductor Class | Tidak. of Cores |

|---|---|---|

| 0.5 | Kelas 1 | 1–36 cores |

| 0.75 | Kelas 1 | 1–36 cores |

| 1.0 | Kelas 1 | 1–36 cores |

| 1.5 | Kelas 2 | 1–36 cores |

| 2.5 | Kelas 2 | 1–36 cores |

| 4 | Kelas 2 | 1–36 cores |

| 6 | Kelas 2 | 1–36 cores |

| 10 | Kelas 2 | 1–36 cores |

These configurations are commonly used for kabel kawalan, auxiliary power circuits, and industrial distribution systems.

Typical Applications

The N2XKFGbY (CU/XLPE/PVC/LS/PVC/SFWA/PVC) 0.6/1 (1.2) kabel kV is widely applied in:

- Loji janakuasa dan pencawang

- Industrial manufacturing facilities

- Underground power distribution

- Tunnels and transportation infrastructure

- Oil, gas, and petrochemical plants

- Utilities and public infrastructure projects

Key Advantages

- Excellent electrical performance

- Perlindungan mekanikal yang kuat

- Superior moisture and chemical resistance

- Hayat perkhidmatan yang panjang

- IEC-compliant conductor configurations

- Suitable for harsh and underground environments

N2XKFGbY (CU/XLPE/PVC/LS/PVC/SFWA/PVC) 0.6/1 (1.2) kabel kV

The N2XKFGbY (CU/XLPE/PVC/LS/PVC/SFWA/PVC) 0.6/1 (1.2) kabel kV is a proven solution for low-voltage power transmission where kekuatan mekanikal, perlindungan alam sekitar, dan kebolehpercayaan jangka panjang are essential. With its lead sheath and steel flat armour design, this cable meets the demands of modern industrial and infrastructure applications.