Introduction to ESP Power Cable Solutions

Электрический погружной насос (Кабель питания ЭСП) systems play a vital role in modern oil and gas production, particularly in high-flow and deep-well applications. To ensure stable operation, these systems require a reliable method to transmit power from the surface to the downhole motor. По этой причине, power cables designed specifically for ESP systems have become a critical component of overall well performance.

Unlike standard industrial cables, downhole power cables must operate continuously under extreme temperature, давление, and chemical exposure. Поэтому, selecting the right manufacturer, cable type, and pricing structure directly influences both operational reliability and lifecycle cost.

Understanding the Role of ESP Power Cables

ESP power cables deliver electrical energy from surface control equipment to submersible motors installed deep inside the wellbore. In most cases, these cables remain in service for years without maintenance.

В то же время, they must withstand several operational challenges, включая:

- Extended installation depths

- Elevated ambient temperatures

- Exposure to oil, gas, water, и агрессивные жидкости

- Mechanical stress during installation and operation

Как результат, cable failure often leads to costly downtime and well intervention. From a practical perspective, cable reliability becomes just as important as pump performance.

Cable Structure and Design Considerations

To meet harsh downhole requirements, manufacturers design ESP cables with multiple functional layers. Each layer contributes to electrical performance, механическая прочность, and environmental resistance.

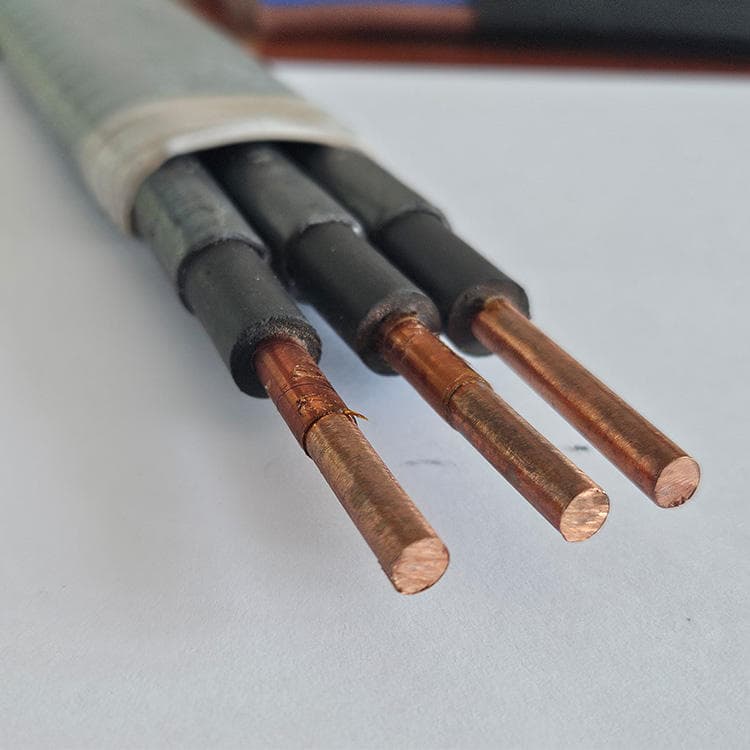

Conductor Design

Most manufacturers use high-purity annealed copper conductors because they offer excellent conductivity and long-term stability. Кроме того, compacted or stranded designs help balance flexibility and current-carrying capacity.

Система изоляции

The insulation layer prevents electrical breakdown under high voltage and temperature conditions. Commonly used materials include polypropylene, ЭПР, СПЭ, and advanced fluoropolymers. Более того, insulation selection directly affects thermal endurance and service life.

Outer Protection

The outer jacket protects the cable against abrasion, chemical attack, и механические повреждения. In demanding wells, engineers often select reinforced or lead-sheathed designs to improve durability.

Main Types of ESP Power Cables

Manufacturers offer several cable configurations to match different well conditions. Однако, each type serves a specific purpose.

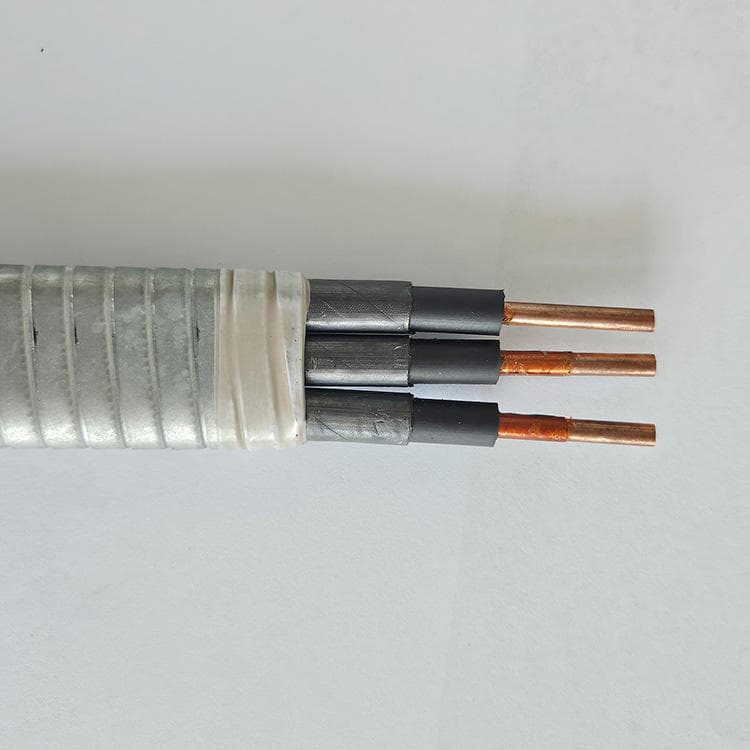

Плоские кабели ESP

Flat cables provide efficient heat dissipation and compact installation. Поэтому, operators frequently use them in standard vertical wells.

Круглые кабели ESP

В отличие, round cables offer higher mechanical strength. Как результат, they perform better in deep or deviated wells where mechanical stress increases.

Lead-Sheathed Cables

When wells contain corrosive fluids or sour gas, lead-sheathed designs become a preferred solution. In addition to chemical resistance, they also act as effective gas barriers.

High-Temperature Cables

For geothermal or high-temperature reservoirs, manufacturers develop cables that maintain stable electrical properties above 200°C. Следовательно, these designs reduce insulation aging and operational risk.

| Cable size,AWG / мм² | Cross-sectionmm² | Дирижер | |

|---|---|---|---|

| Quantity | Conductor type | ||

| 1 AWG | 42.41 | 1 | твердый |

| 7 | stranded compacted | ||

| 2 AWG | 33.63 | 1 | твердый |

| 7 | stranded compacted | ||

| 4 AWG | 21.15 | 1 | твердый |

| 16 мм² | 16.00 | 1 | твердый |

| 6 AWG | 13.29 | 1 | твердый |

| 10 мм² | 10.00 | 1 | твердый |

| 8 мм² | 8.00 | 1 | твердый |

ESP Power Cable Manufacturing Process

A professional cable producer follows a controlled manufacturing workflow to ensure consistent quality.

Первый, technicians qualify all raw materials through electrical and mechanical testing. Следующий, they strand and compact the copper conductor to precise dimensional tolerances. After that, extrusion lines apply insulation with strict thickness control.

Окончательно, curing, jacketing, and comprehensive testing confirm that each cable meets project specifications. Поэтому, quality assurance plays a central role throughout the entire process.

Industry Standards and Compliance

To ensure compatibility and safety, manufacturers design ESP cables according to recognized industry standards, including API and IEC requirements. Более того, many projects require additional customer-specific testing and third-party inspection.

Factors Influencing ESP Power Cable Pricing

Cable pricing depends on several technical and commercial factors. Например:

- Conductor size and copper content

- Insulation and jacket material selection

- Cable configuration and temperature rating

- Order volume and testing requirements

Как результат, prices vary significantly from one project to another. For accurate quotations, suppliers usually request detailed operating conditions.

Market Trends and Future Development

As wells become deeper and hotter, cable technology continues to evolve. Manufacturers now focus on advanced insulation systems, improved chemical resistance, and longer service life. В то же время, cost optimization remains a key consideration for operators.

ESP power cable Manufacturer-DOS CABLE

ESP power cables directly influence the reliability and efficiency of submersible pump systems. Поэтому, understanding cable types, manufacturing practices, and pricing drivers helps operators make better technical and commercial decisions. By working with experienced manufacturers and selecting the right cable design, long-term performance and operational safety can be significantly improved.