Perkenalan

As global power transmission networks continue to expand and upgrade, tegangan tinggi (Hv) dan tegangan ekstra tinggi (EHV) sistem kabel bawah tanah telah menjadi bagian penting dari infrastruktur kelistrikan modern. Urbanisasi, integrasi energi terbarukan, interkoneksi lintas batas, dan penggantian saluran udara yang sudah tua mendorong permintaan akan sistem kabel bawah tanah dan bawah laut yang andal. Within these systems, 66kV/132kV/145kV/230kV Cable Straight Joint play an indispensable role.

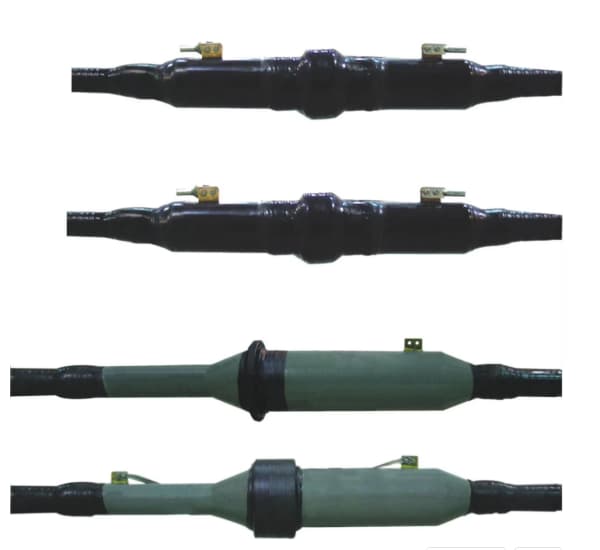

A cable straight joint splice is used to connect two sections of power cable in a straight line, ensuring electrical continuity, mechanical integrity, and long-term insulation performance equivalent to or better than the original cable. For voltage classes such as 66persegi panjang, 132persegi panjang, 145persegi panjang, and 230kV, the design and manufacturing of straight joint kits require advanced materials, precise engineering, and strict compliance with international standards.

1. Role of Cable Straight Joint Splices in HV Power Systems

In high-voltage cable systems, joints are statistically the most critical components. While the cable itself is factory-manufactured under highly controlled conditions, joints are typically installed in the field. A properly designed straight joint splice must:

- Restore the electrical characteristics of the cable

- Maintain uniform electric field distribution

- Provide long-term insulation reliability

- Ensure mechanical strength and flexibility

- Offer moisture, kimia, dan ketahanan terhadap korosi

For voltage levels of 66persegi panjang, 132persegi panjang, 145persegi panjang, and 230kV, even minor imperfections in joint design or installation can lead to partial discharge, thermal runaway, or catastrophic failure. Karena itu, straight joint splice kits are engineered as complete systems rather than simple accessories.

2. 66kV/132kV/145kV/230kV Cable Straight Joint Voltage Classes and Typical Applications

2.1 66Sambungan Sambungan Lurus Kabel kV

66kV systems are widely used in sub-transmission networks, pabrik industri, wind farms, and medium-distance underground links. Straight joint kits for this voltage level must balance compact design with reliable insulation performance.

2.2 132Sambungan Sambungan Lurus Kabel kV

132kV is one of the most common HV voltage levels globally. These joints are frequently used in urban underground networks, power stations, and cross-river or cross-road installations. High reliability and long service life are key requirements.

2.3 145Sambungan Sambungan Lurus Kabel kV

145kV is often associated with IEC standardization and international projects. Straight joint splices at this level are typically designed with higher insulation margins and stricter testing protocols.

2.4 230Sambungan Sambungan Lurus Kabel kV

230kV cable systems are classified as EHV. Straight joint kits for this voltage class are used in long-distance transmission, renewable energy export cables, and critical infrastructure. Advanced stress control and insulation technologies are essential.

3. Cable Types Supported by Straight Joint Kits

Modern straight joint splice kits are designed to be compatible with various cable constructions, including:

- XLPE insulated copper cables

- XLPE insulated aluminum cables

- Single-core HV cables

- Armored and unarmored designs

- Underground and submarine cables

The joint design must match the cable insulation thickness, Ukuran konduktor, screen configuration, and sheath type to ensure optimal performance.

4. Design Principles of HV Cable 66kV/132kV/145kV/230kV Cable Straight Joint

4.1 Electrical Field Control

At high voltages, electric field concentration is the primary cause of insulation degradation. Straight joint splices use stress control components such as:

- Kerucut tegangan yang sudah dibentuk sebelumnya

- Geometric field grading elements

- Resistive or capacitive stress control layers

These components ensure smooth electric field distribution across the joint area.

4.2 Insulation System

The insulation system in a straight joint splice must provide dielectric strength equivalent to the cable insulation. Common insulation materials include:

- Silicone rubber

- EPDM rubber

- Cross-linked polyolefin

Untuk aplikasi 230kV, multi-layer insulation systems are typically employed.

4.3 Koneksi Konduktor

The conductor connector is a critical mechanical and electrical component. It must provide:

- Low contact resistance

- High mechanical strength

- Compatibility with copper or aluminum conductors

Shear bolt connectors and compression connectors are commonly used, depending on conductor size and project requirements.

5. IEC Conductor Sizes from 50 mm² sampai 2500 mm²

Straight joint splice kits are manufactured to accommodate a wide range of conductor sizes defined by IEC standards. Below is a comprehensive technical table covering IEC conductors from 50 mm² sampai 2500 mm², suitable for copper and aluminum conductors.

IEC Standard Conductor Size Table

| IEC Conductor Size (mm²) | Typical Conductor Material | Kira-kira. DC Resistance (Oh/km, Cu @20°C) | Kira-kira. DC Resistance (Oh/km, Al @20°C) | Typical Application Voltage |

|---|---|---|---|---|

| 50 | Cu / Al | 0.387 | 0.641 | 66persegi panjang |

| 70 | Cu / Al | 0.268 | 0.443 | 66persegi panjang |

| 95 | Cu / Al | 0.193 | 0.320 | 66persegi panjang |

| 120 | Cu / Al | 0.153 | 0.253 | 66persegi panjang / 132persegi panjang |

| 150 | Cu / Al | 0.124 | 0.206 | 66persegi panjang / 132persegi panjang |

| 185 | Cu / Al | 0.0991 | 0.164 | 132persegi panjang |

| 240 | Cu / Al | 0.0754 | 0.125 | 132persegi panjang / 145persegi panjang |

| 300 | Cu / Al | 0.0601 | 0.100 | 132persegi panjang / 145persegi panjang |

| 400 | Cu / Al | 0.0470 | 0.0778 | 145persegi panjang |

| 500 | Cu / Al | 0.0366 | 0.0605 | 145persegi panjang / 230persegi panjang |

| 630 | Cu / Al | 0.0283 | 0.0469 | 230persegi panjang |

| 800 | Cu / Al | 0.0221 | 0.0366 | 230persegi panjang |

| 1000 | Cu / Al | 0.0176 | 0.0293 | 230persegi panjang |

| 1200 | Cu / Al | 0.0147 | 0.0245 | 230persegi panjang |

| 1600 | Cu / Al | 0.0110 | 0.0183 | 230persegi panjang |

| 2000 | Cu / Al | 0.0088 | 0.0146 | 230persegi panjang |

| 2500 | Cu / Al | 0.0070 | 0.0116 | 230persegi panjang |

Catatan: Resistance values are indicative and may vary depending on conductor construction and IEC standard edition.

6. Manufacturing Process of 66kV/132kV/145kV/230kV Cable Straight Joint

6.1 Pemilihan Bahan

High-quality raw materials are essential for long-term performance. Manufacturers select materials with proven dielectric, panas, and mechanical properties.

6.2 Precision Molding and Assembly

Pre-molded joints are manufactured using high-precision tooling to ensure dimensional accuracy. Each component is designed to fit perfectly with the cable dimensions.

6.3 Quality Control

Every straight joint splice kit undergoes rigorous inspection, including:

- Dimensional checks

- Material property verification

- Electrical routine tests

7. Installation Considerations

Proper installation is as important as product quality. Key factors include:

- Correct cable preparation

- Clean working environment

- Accurate positioning of stress control elements

- Proper tightening of connectors

Manufacturers typically provide detailed installation manuals and on-site training support.

8. Testing Standards and Type Tests

Straight joint splices for 66kV–230kV applications are tested according to international standards such as:

- IEC 60840 (for 66kV–150kV)

- IEC 62067 (for 150kV–500kV)

Type tests include:

- AC voltage withstand test

- Partial discharge measurement

- Thermal cycling test

- Lightning impulse test

9. Reliability and Service Life

A properly designed and installed straight joint splice can achieve a service life of 30–40 years, matching the expected life of the cable itself. Advanced materials and improved field control designs have significantly reduced failure rates in modern HV cable systems.

10. Choosing a Reliable Cable Kits Manufacturer

When selecting a manufacturer for 66kV–230kV cable straight joint splices, key evaluation criteria include:

- Compliance with IEC standards

- Proven project references

- Ability to cover conductor sizes from 50 mm² sampai 2500 mm²

- Technical support and customization capability

A reliable manufacturer not only supplies products but also provides engineering expertise throughout the project lifecycle.

11.66persegi panjang / 132persegi panjang / 145persegi panjang / 230kV Cable Straight Joint

Cable straight joint splices are critical components in high-voltage and extra-high-voltage cable systems. For voltage classes 66persegi panjang, 132persegi panjang, 145persegi panjang, and 230kV, joint kits must deliver exceptional electrical performance, mechanical reliability, and long-term durability.

By supporting IEC conductor sizes from 50 mm² sampai 2500 mm², modern straight joint splice kits offer flexibility for a wide range of applications, from compact urban networks to large-scale EHV transmission projects. With proper design, manufacturing, and installation, these joints ensure the safe and efficient operation of power networks for decades to come.

As global demand for underground and submarine power transmission continues to grow, high-quality cable straight joint splices will remain a cornerstone of reliable energy infrastructure.