Kabel Bawah Laut

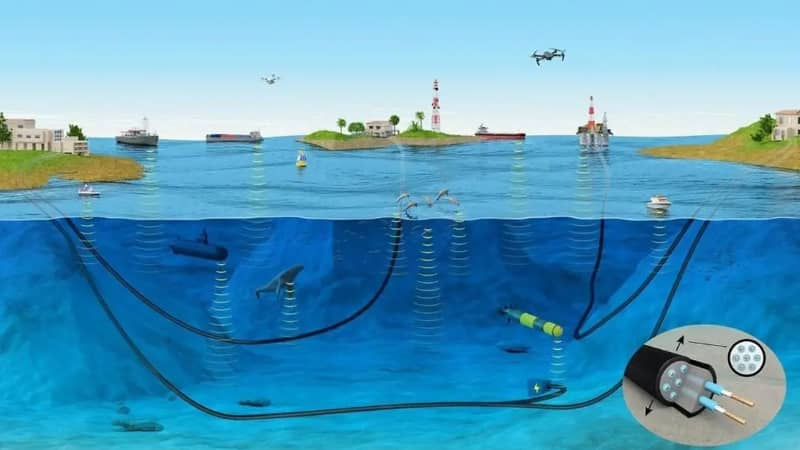

Kabel Bawah Laut dirancang untuk transmisi daya dan sinyal yang andal di lingkungan bawah laut dan lepas pantai, dimana kabel harus tahan terhadap tekanan air, korosi, dan tekanan mekanis.

Sebagai produsen kabel profesional, kami fokus pada struktur produk, menggunakan konduktor berkualitas tinggi, isolasi tingkat lanjut, selubung timah dan perlindungan multilapis untuk memastikan kinerja listrik yang stabil.

Proses produksi kami meliputi konduktor yang terdampar, ekstrusi isolasi, selubung timah , pelindung, dan selubung, semua dieksekusi di bawah kontrol proses yang ketat.

Setiap kabel bawah laut diuji integritas kelistrikannya, kekuatan mekanik, dan kinerja penyegelan sebelum pengiriman.

Melalui manufaktur standar dan kontrol kualitas, kami menyediakan produk kabel bawah laut yang tahan lama dan konsisten untuk aplikasi kelautan.

Jenis Kabel Bawah Laut

Kabel Listrik Bawah Laut

Kabel Listrik Bawah Laut dirancang untuk transmisi daya yang stabil dan jangka panjang dalam aplikasi lepas pantai dan bawah laut, dengan peringkat tegangan mulai dari 5 persegi panjang, 10persegi panjang,15persegi panjang,20persegi panjang, 30persegi panjang, 35persegi panjang,66persegi panjang, 132persegi panjang, 230 persegi panjang.

Kabel dirancang untuk beroperasi dengan andal di bawah tekanan air terus menerus, lingkungan laut yang korosif, dan kondisi dasar laut yang kompleks.

Konduktor berkualitas tinggi dikombinasikan dengan sistem insulasi canggih memastikan kehilangan listrik yang rendah dan kinerja termal yang konsisten selama pengoperasian.

Kabel Komunikasi Bawah Laut

Kabel komunikasi bawah laut mengirimkan lalu lintas internet global melintasi lautan menggunakan serat optik, mengaktifkan dengan cepat, dapat diandalkan, konektivitas internasional latensi rendah di seluruh dunia.

Mereka membentuk infrastruktur penting yang menghubungkan benua, mendukung layanan cloud, jaringan keuangan, streaming video, riset, keamanan, dan komunikasi digital sehari-hari secara global.

Kabel mengandung inti serat lapis baja, konduktor listrik, isolasi, dan repeater, dirancang untuk menahan tekanan, korosi, arus, gempa bumi, dan dampak penangkapan ikan.

Kabel Serat Optik Bawah Laut

Kabel Serat Optik Bawah Laut dirancang untuk transmisi data berkecepatan tinggi di lingkungan lepas pantai dan bawah laut dengan keandalan jangka panjang.

Struktur kabel melindungi serat optik dari tekanan air, korosi, dan tekanan mekanis selama pemasangan dan pengoperasian.

Bahan canggih dan manufaktur presisi memastikan kehilangan sinyal rendah dan kinerja stabil pada jarak transmisi jauh.

Lapisan penahan air dan selubung luar yang kuat memberikan perlindungan efektif terhadap masuknya kelembapan dan kerusakan eksternal.

Kabel Tahan Air

Kabel Tahan Air dirancang untuk aplikasi daya tegangan rendah yang membutuhkan kinerja andal dalam kondisi lembab, basah, atau kondisi lingkungan terendam di seluruh dunia.

Kabel menggunakan bahan insulasi tahan lembab untuk mencegah masuknya air dan menjaga kestabilan karakteristik kelistrikan selama pengoperasian jangka panjang.

Kabel Tahan Air cocok untuk penerangan, kontrol, dan sistem distribusi tenaga listrik yang terkena kelembaban dalam aplikasi instalasi industri dan komersial.

Sambungan Kabel Bawah Laut

Sambungan Kabel Bawah Laut dirancang untuk menyediakan sambungan listrik dan mekanis yang andal untuk sistem kabel bawah laut.

Struktur sambungan memastikan kinerja penyegelan yang sangat baik untuk mencegah masuknya air dalam kondisi bawah laut jangka panjang.

Desainnya mengakomodasi pergerakan kabel, ketegangan, dan ekspansi termal selama lingkungan operasi kapal selam.

Aksesoris Terminal Kabel Bawah Laut

Aksesori Terminal Kabel Bawah Laut dirancang untuk memastikan terminasi kabel listrik bawah laut yang aman dan andal.

Aksesori ini memberikan insulasi listrik dan kinerja penyegelan yang efektif dalam kondisi lingkungan laut yang keras.

Bahan berkualitas tinggi digunakan untuk menahan kelembapan, korosi, dan tekanan termal selama operasi jangka panjang.

Desain terminal mendukung sambungan listrik yang stabil dan perlindungan mekanis pada titik transisi di darat.

Parameter Teknis Kabel Bawah Laut

Parameter teknis Kabel Bawah Laut menentukan kelistrikannya, mekanis, dan kinerja lingkungan yang diperlukan untuk operasi bawah laut jangka panjang yang andal.

Level tegangan terukur biasanya berkisar dari kelas tegangan rendah hingga tegangan tinggi, tergantung pada jarak transmisi dan persyaratan aplikasi.

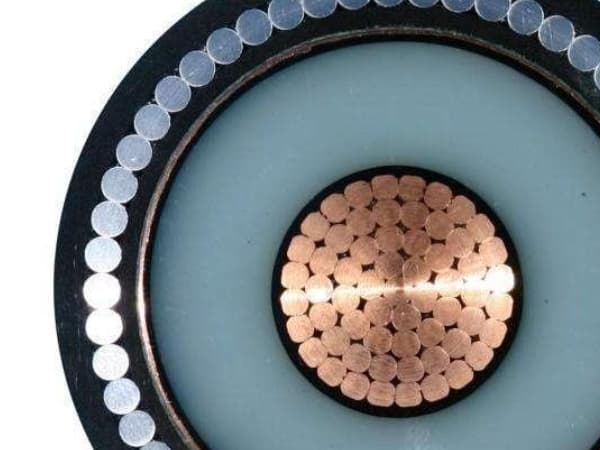

Bahan konduktor biasanya tembaga atau aluminium, dirancang dengan stranding kompak untuk memastikan resistansi rendah dan kapasitas arus stabil.

Sistem isolasi dipilih berdasarkan kelas tegangan, umumnya menggunakan XLPE atau EPR untuk memberikan kekuatan dielektrik yang sangat baik.

Lapisan penyaringan logam memastikan medan listrik seragam dan memungkinkan grounding yang efektif untuk pengoperasian kabel yang aman dan stabil.

Parameter pemblokiran air secara radial dan longitudinal sangat penting, mencegah masuknya uap air di bawah tekanan hidrostatik terus menerus.

Opsi selubung timah atau penghalang logam memberikan peningkatan kinerja penyegelan untuk lingkungan kapal selam dan lepas pantai yang menantang.

Parameter mekanis meliputi kekuatan tarik, radius lentur, dan ketahanan benturan selama pemasangan peletakan dan dasar laut.

Spesifikasi lapis baja menentukan jenis kawat baja, struktur lapisan, dan perlindungan korosi untuk keamanan mekanis.

Semua parameter teknis diverifikasi secara rutin, jenis, dan tes penerimaan sesuai standar internasional.

Situs Pemasangan Kabel Bawah Laut Kami

Lokasi pemasangan kabel bawah laut kami menunjukkan pelaksanaan profesional proyek pemasangan kabel lepas pantai dan bawah laut dalam kondisi operasional yang terkendali.

Lokasi ini dipilih secara cermat berdasarkan survei dasar laut, analisis kedalaman air, dan penilaian dampak lingkungan.

Kapal dan peralatan khusus dikerahkan untuk memastikan penanganan yang aman, penentuan posisi, dan mengendalikan ketegangan selama pemasangan kabel.

Drum kabel, penegang, dan sistem pemandu diatur untuk mencegah kerusakan mekanis selama proses peletakan.

Prosedur ketat diikuti untuk pembayaran kabel, penyelarasan, dan pendaratan dasar laut untuk memastikan keandalan jangka panjang.

Insinyur berpengalaman memantau parameter pemasangan termasuk radius tekukan, kekuatan menarik, dan kecepatan peletakan secara real time.

Operasi penyambungan dan terminasi dilakukan di zona terlindungi menggunakan peralatan yang disetujui dan teknisi bersertifikat.

Langkah-langkah perlindungan lingkungan diterapkan untuk meminimalkan gangguan dasar laut dan mematuhi peraturan kelautan.

Semua aktivitas instalasi mengikuti standar internasional dan spesifikasi proyek untuk memastikan kualitas dan keamanan yang konsisten.

Lokasi pemasangan mencerminkan kemampuan kami untuk memberikan solusi kabel bawah laut yang lengkap mulai dari manufaktur hingga penerapan akhir.

Produsen Kabel Bawah Laut - DUA KAWAT

DOS CABLE adalah produsen profesional yang mengkhususkan diri dalam produksi kabel listrik dan komunikasi bawah laut.

Kami fokus pada kinerja yang stabil, daya tahan, dan keselamatan untuk lingkungan lepas pantai yang menuntut.

Kabel bawah laut kami dirancang untuk menahan tekanan air, korosi, dan tekanan mekanis.

Jalur produksi yang canggih memastikan proses pelepasan konduktor dan ekstrusi insulasi yang tepat.

Pemilihan material yang ketat menjamin kinerja listrik dan mekanik yang konsisten.

Berbagai struktur kabel tersedia untuk kedalaman air dan kondisi pemasangan yang berbeda.

Pengujian internal yang komprehensif memastikan kepatuhan terhadap standar kabel bawah laut internasional.

Mengapa Memilih Kabel DOS untuk Kabel Bawah Laut?

Kami menyediakan solusi kabel bawah laut yang disesuaikan berdasarkan persyaratan teknis proyek.

KABEL DOS memberikan kualitas yang dapat diandalkan, keahlian manufaktur, dan dukungan proyek jangka panjang.